I discovered that our Leaf does not charge on AC chargers (we have not tried DC Chademo since the one in our city is removed permanently).

1. After charging, one blue light comes on for few seconds and it then turns off.

2. I tried to measure resistance/diode polarity on ground/pilot but did not see low resistance. In one direction I read about 0.4 Mega Ohms and in reverse it seemed open.

3. I suspected that the 12 V battery was poor (showing 12.2 V), so I charged it overnight. I installed it and saw it again showing 12.2V on the car and 12.38 free. I suspected a poor battery, and bought and installed a new battery. It did not solve the problem. I also noted that a 2.2 A (that drops to 1.5A) is drawn when all I install the battery and all of the lights are off.

4. I got these from leaf Spy Pro:

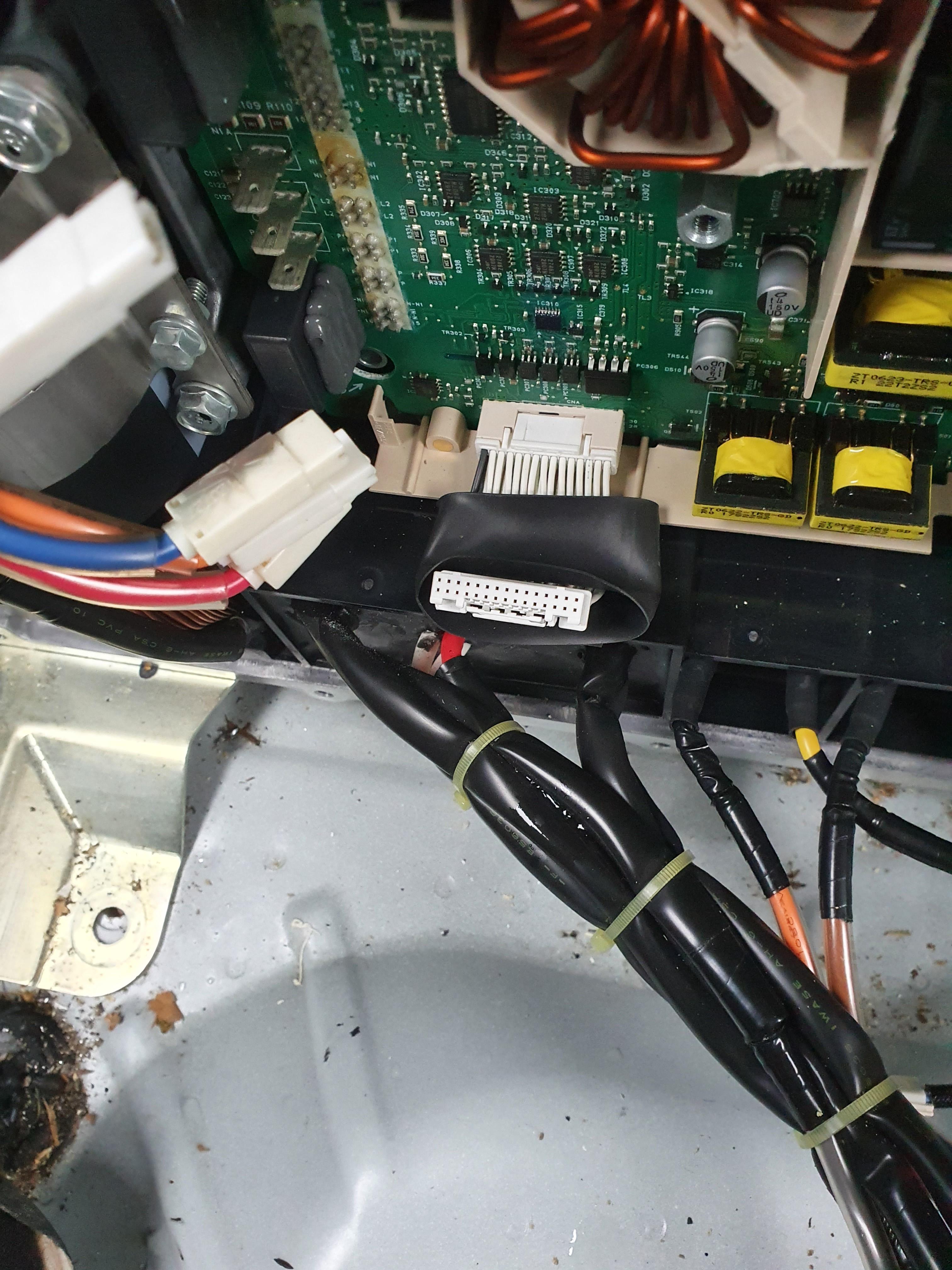

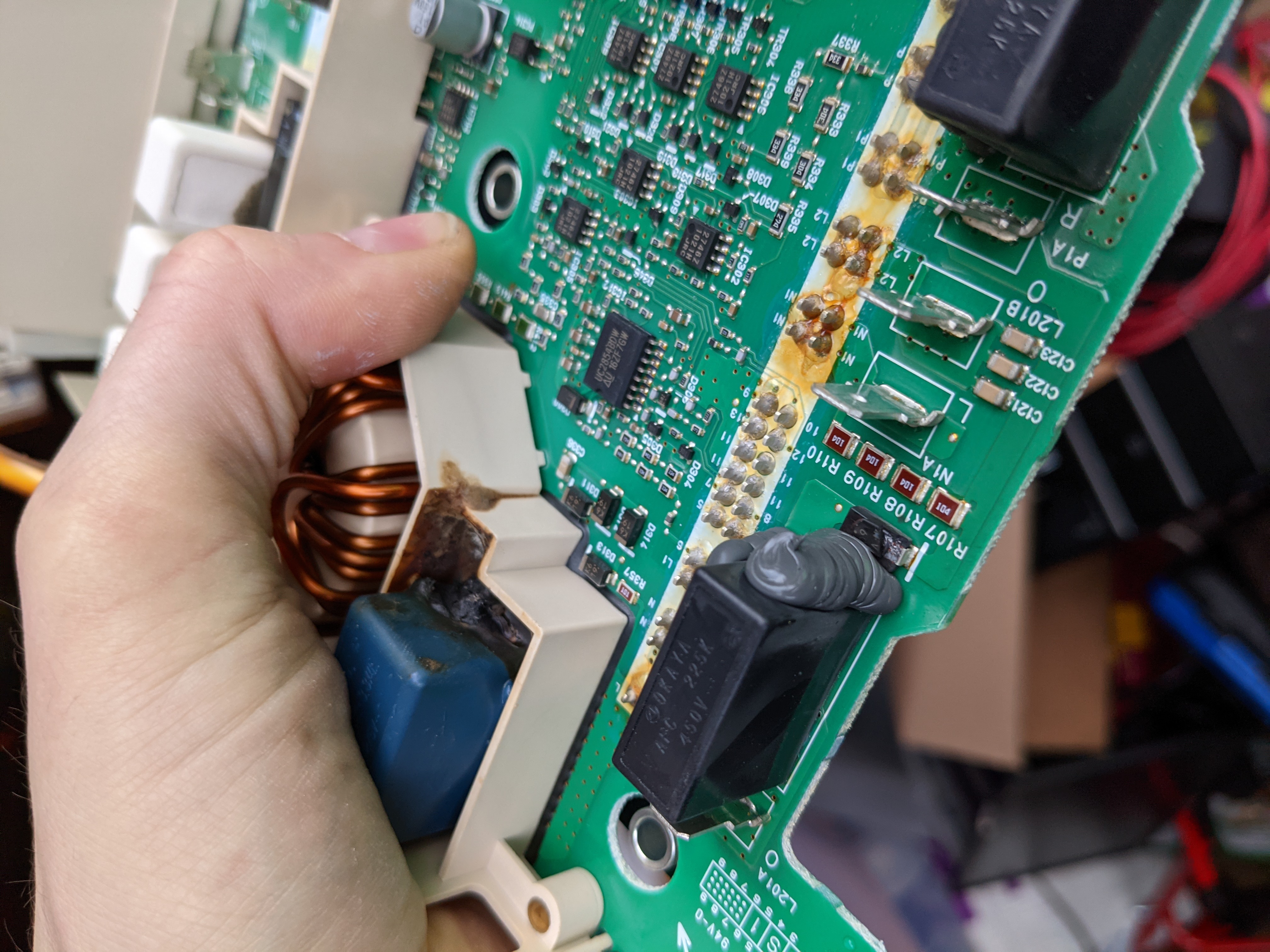

I guess some of the above codes were due to low 12V battery, but now I am pretty sure that the On-board charger is in trouble. I am wondering what will be the best next action, taking it to the dealership (I think I can reach it with the remaining charge), or buying a second hand on-board charger from an accident write-off Leaf [does it need to be exactly the same]. I wonder if more experienced forum members can help me decide.

As you can guess, I have searched and read about Leafs with similar problems in this forum.

1. After charging, one blue light comes on for few seconds and it then turns off.

2. I tried to measure resistance/diode polarity on ground/pilot but did not see low resistance. In one direction I read about 0.4 Mega Ohms and in reverse it seemed open.

3. I suspected that the 12 V battery was poor (showing 12.2 V), so I charged it overnight. I installed it and saw it again showing 12.2V on the car and 12.38 free. I suspected a poor battery, and bought and installed a new battery. It did not solve the problem. I also noted that a 2.2 A (that drops to 1.5A) is drawn when all I install the battery and all of the lights are off.

4. I got these from leaf Spy Pro:

C1109 0008 ABS Battery Voltage Abnormal BRC-75

C118A 0108 ABS E-Driven Int Brake System BRC-124

U11 OD 0108 ABS E-Driven Intelligent Brake Comm BRC-130

C118C 0108 ABS EV/HEVSystem BRC-126

Ok None---> AIIR BAG

U1000 0008 BCM CAN Comm Circuit

82562 0008 BCM Low Voltage BCS-69

82604 0008 BCM Shift PN Diag CAN SEC-81

826EF 0008 BCM

C1A62 0108 BRAKE Control Mod Pwr Supply BR-53

C1A6E 0108 BRAKE EV/HEV System BR-146

C1A70 0108 BRAKE Brake Control System BR-160

U1511 0108 BRAKE Pwr Supply Backup Unit Comm BR-184

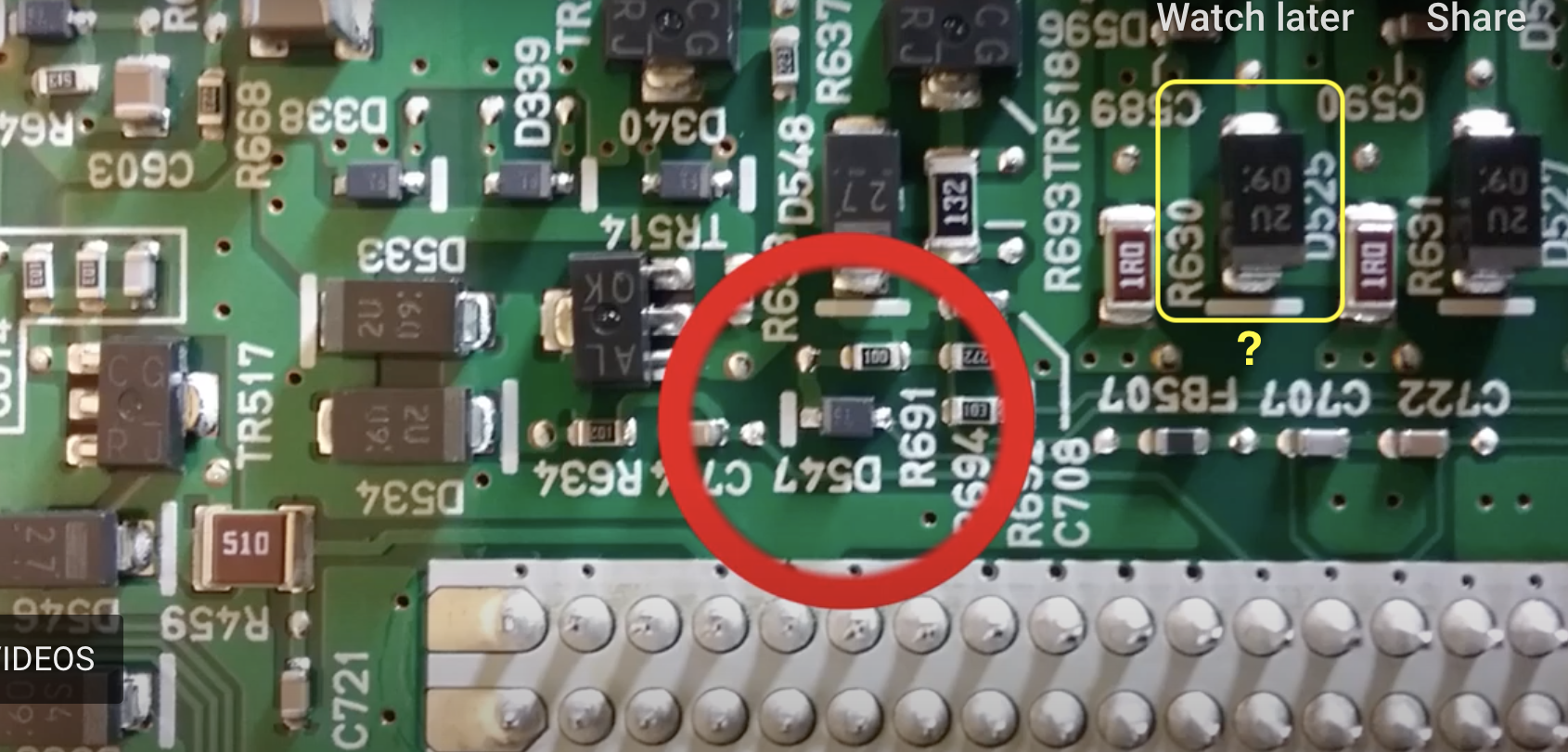

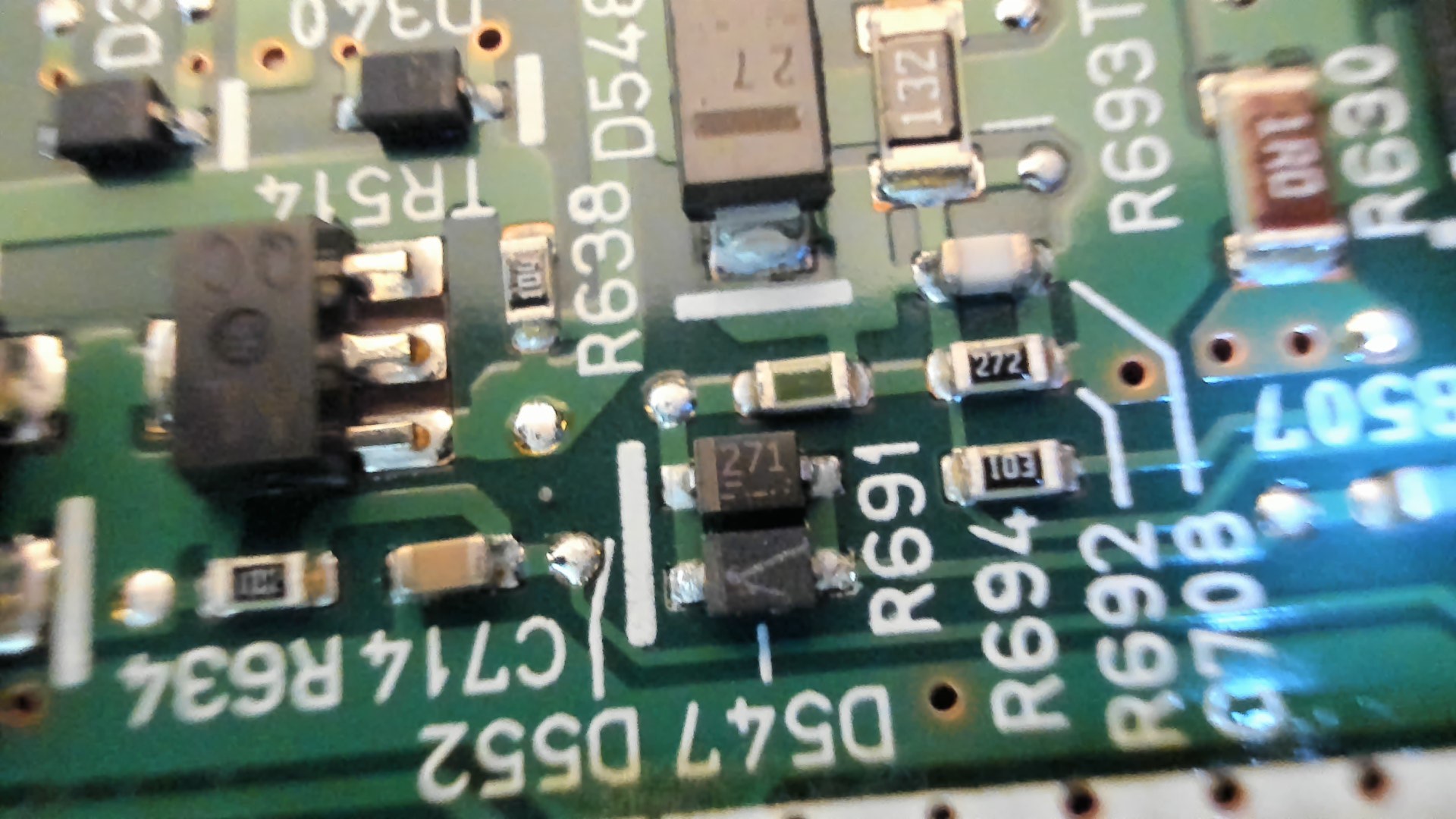

829A0 2968 CHARGER N/CHG Port Engage Err VC-95

829C1 236C CHARGER EVSE VC-98

82820 0028 CHARGER Quick Charger VC-63

U1008 876C CHARGER Quick Charger Comm VC-49

82902 4228 CHARGER OBC Memory Error VC-91

Ok None---> PARKING BRAKE

Ok None ---> EPS

>P3173 00C1 EV /HEV On Board Charger Sys EVC-236

Ok None---> HVAC

Ok None---> HV BATTERY

82109 0008 IPDM E/R

Ok None---> METER

Ok None ---> MOTOR CONTROL

U1300 0108 MULTI AV AV Comm Ci rcuit AV-93

U1240 0208 MULTI AV Switch Conn AV-93

U1232 0108 MULTI AV St Angle Sen Calib AV-88

Ok None---> SHIFT

U1A05 0008 TCU USB Comm AV-199

I guess some of the above codes were due to low 12V battery, but now I am pretty sure that the On-board charger is in trouble. I am wondering what will be the best next action, taking it to the dealership (I think I can reach it with the remaining charge), or buying a second hand on-board charger from an accident write-off Leaf [does it need to be exactly the same]. I wonder if more experienced forum members can help me decide.

As you can guess, I have searched and read about Leafs with similar problems in this forum.