electronit

Member

I think we all have similar intentions  . Apart from the LCD & amp select button, I'd also like to add a button for start/stop. And maybe even (far future) a kWh counter...

. Apart from the LCD & amp select button, I'd also like to add a button for start/stop. And maybe even (far future) a kWh counter...

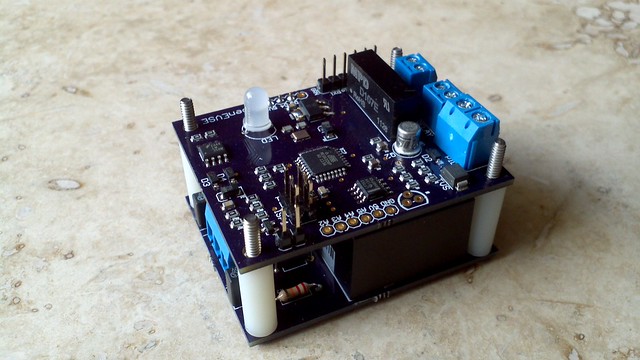

Just received my usb programmer interface, and installed the arduino package. Now just waiting for the rest of the components to arrive.

Just received my usb programmer interface, and installed the arduino package. Now just waiting for the rest of the components to arrive.