Hey Guys,

About a year ago while messing about with different gear oils, I started hearing a humming noise from my gearbox and was certain that my gearbox was going bad. I then got busy building a sauna and have been ignoring the cars. I kept driving the car with the humming noise and it slowly got a bit louder. It got loud enough that I made time for cars again and long story short, it was my wheel bearing, as the noise was still there after replacing the gearbox. The good news is though, that now I can contribute with a video and how-to on this website for getting this job done I don't think this has been posted yet, but if it has then I couldn't find it.

I don't think this has been posted yet, but if it has then I couldn't find it.

The short and sweet route first, I tried to gopro this process the best that I could and leave out any fluff or bullshit that a ton of youtube videos have these days. Per the timestamps on the gopro this took me 9 hours, but i took several breaks in between as well as lunch and dinner, so expect this to be a most of the day type of a job.

https://www.youtube.com/watch?v=4RfyN_ZOt-g

Special tools required:

- 32mm socket for axle nut

- New o-ring for motor output if yours is old (need to dig up what this part number is still)

- Lithium-based grease including molybdenum disulphide.

Torque Specs:

Front Axle Nut - 135 ft lbs

Tie Rod Nut - 25 ft lbs

Transmission Attachment Bolts (16mm) - 37 ftlbs

Transmission Mount Bolts (18mm) - 74 ft lbs

Smaller 13 mm bolts, 18 ft lbs

Upright Bolts to Strut 103 ft lbs

Lug Nuts 85 ft lbs

The short and sweet of it is, this can all be done with basic tools and a bit of muscle. The gearbox itself weighs about 30 lbs so it is not the easiest thing to bench press up and down, but totally doable.

Going to keep the how-to portion of pictures/text short, as the video should cover things in better detail.

Start by jacking up the car, I chose these subframe points to put the jacks under:

Pull out the 12V battery as well as the high voltage battery jumper in front of the rear seats.

After draining the gearbox oil, then pull out both axles (I learned this about half way through the video, can't get a couple of the transmission bolts off the motor without also pulling the passenger side axle). The mount for the passenger side axle is ultimately what gets in the way. Luckily the axles come out with fairly little effort.

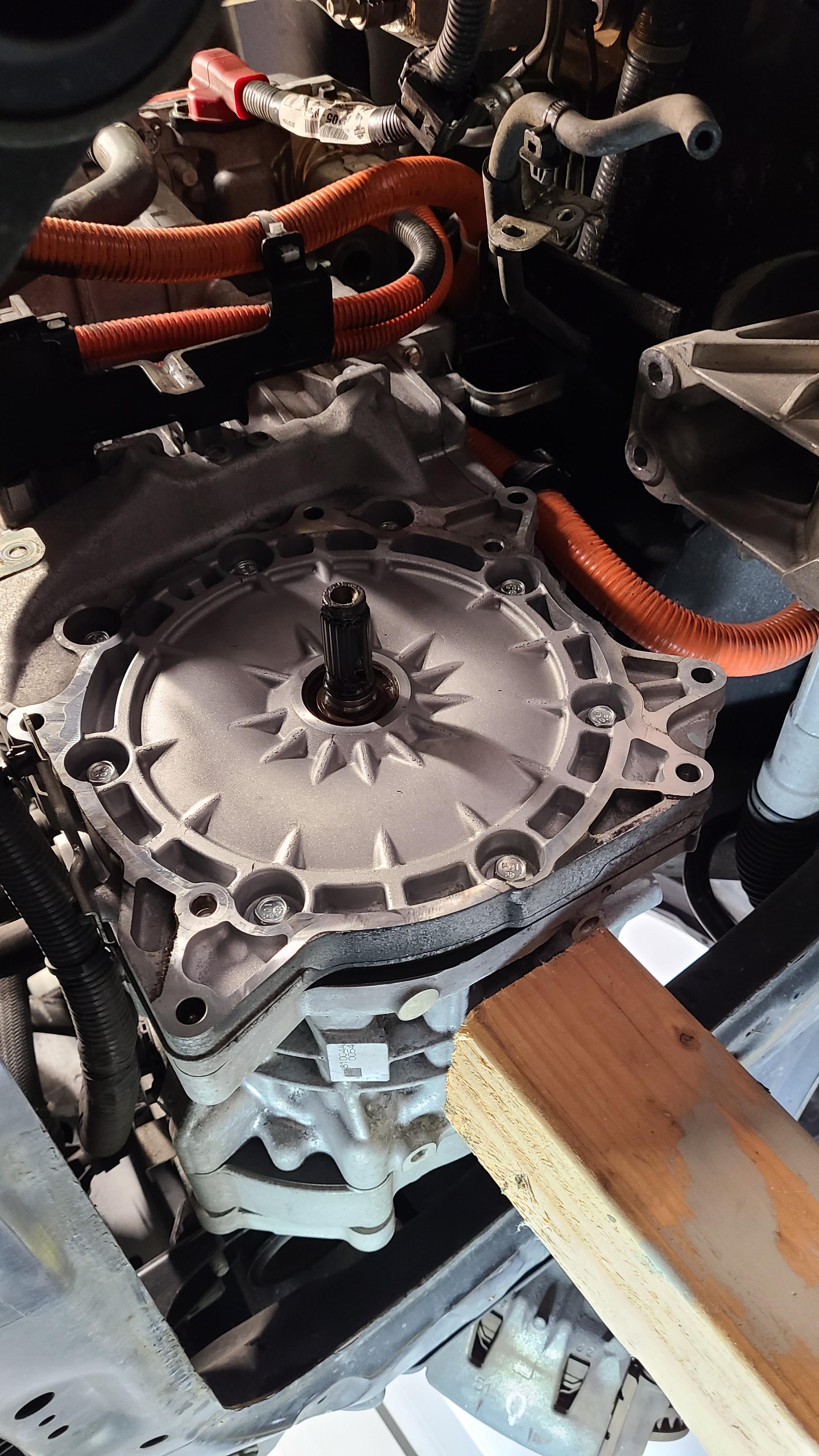

Once the axles are out, support the bottom of the motor with a jack or a wooden support stand. This will allow you to take off the front and rear motor mounts, held on by four 18mm bolts each. The front mount also has a smaller nut holding it onto a rubber mount, once you remove this, the whole front mount comes out of the car.

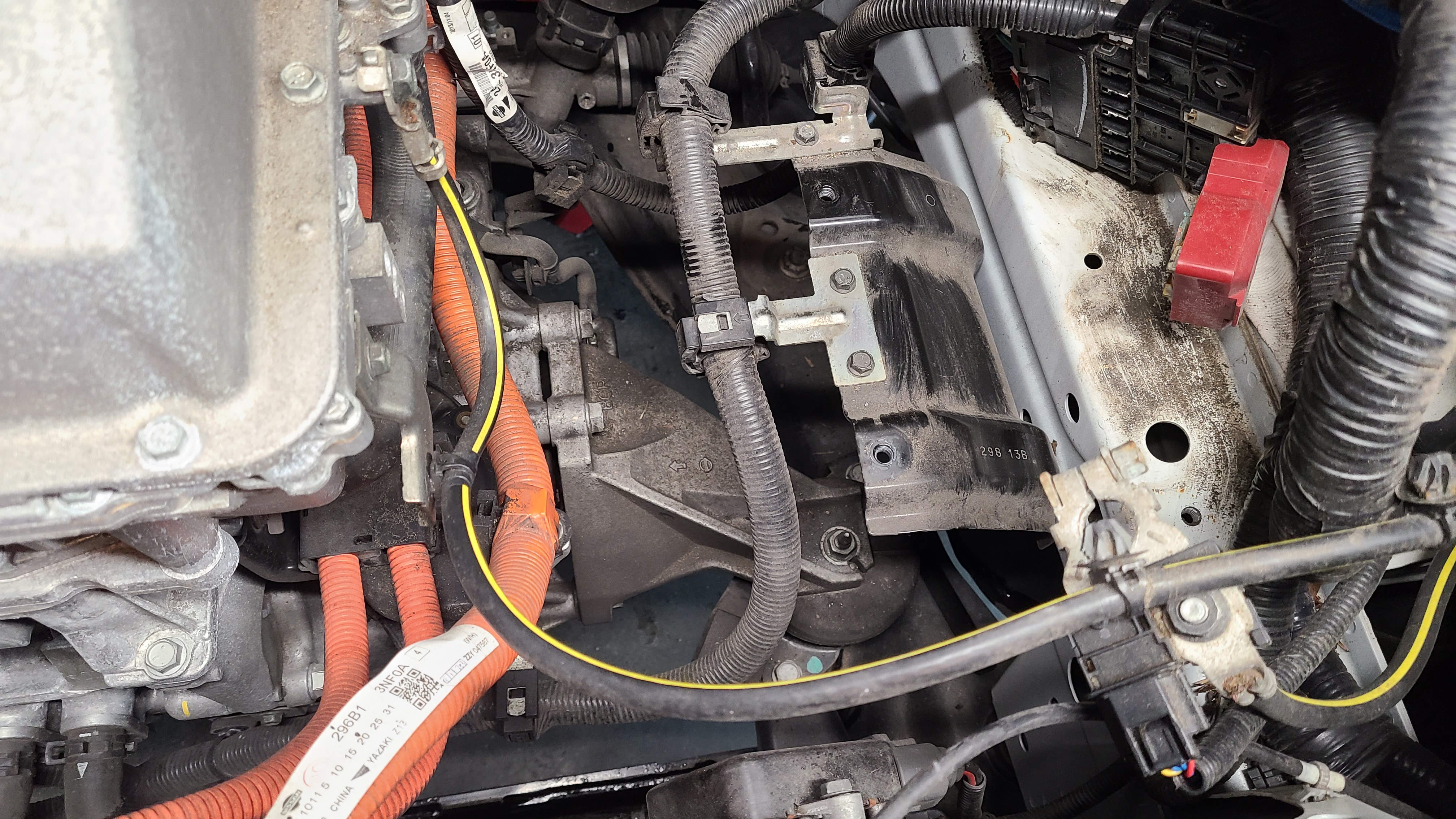

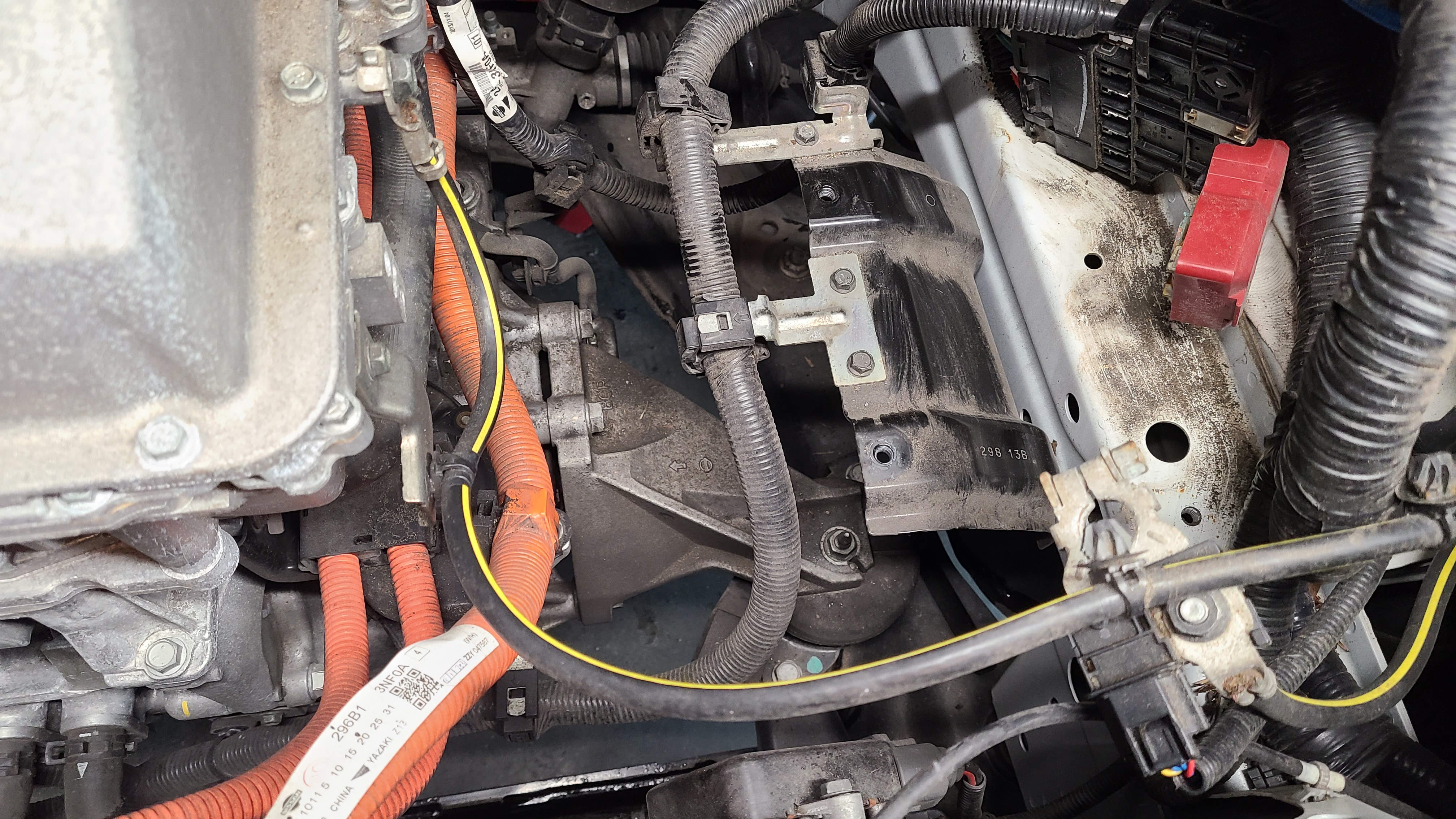

With all the transmission mounting bolts out of the way and the front mount out of the car, you should be able to put a prybar under the transmission about here and pop the transmission loose:

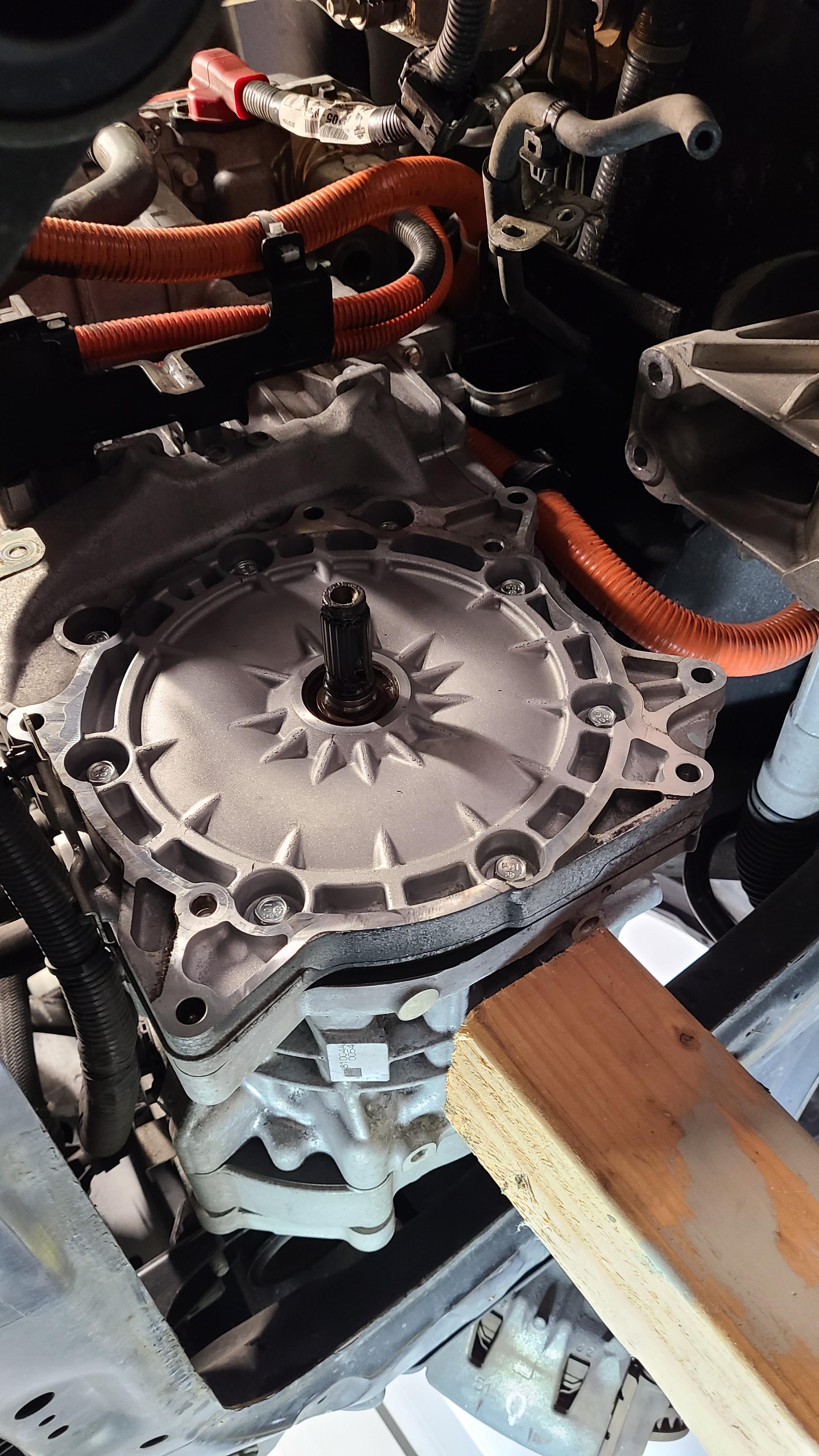

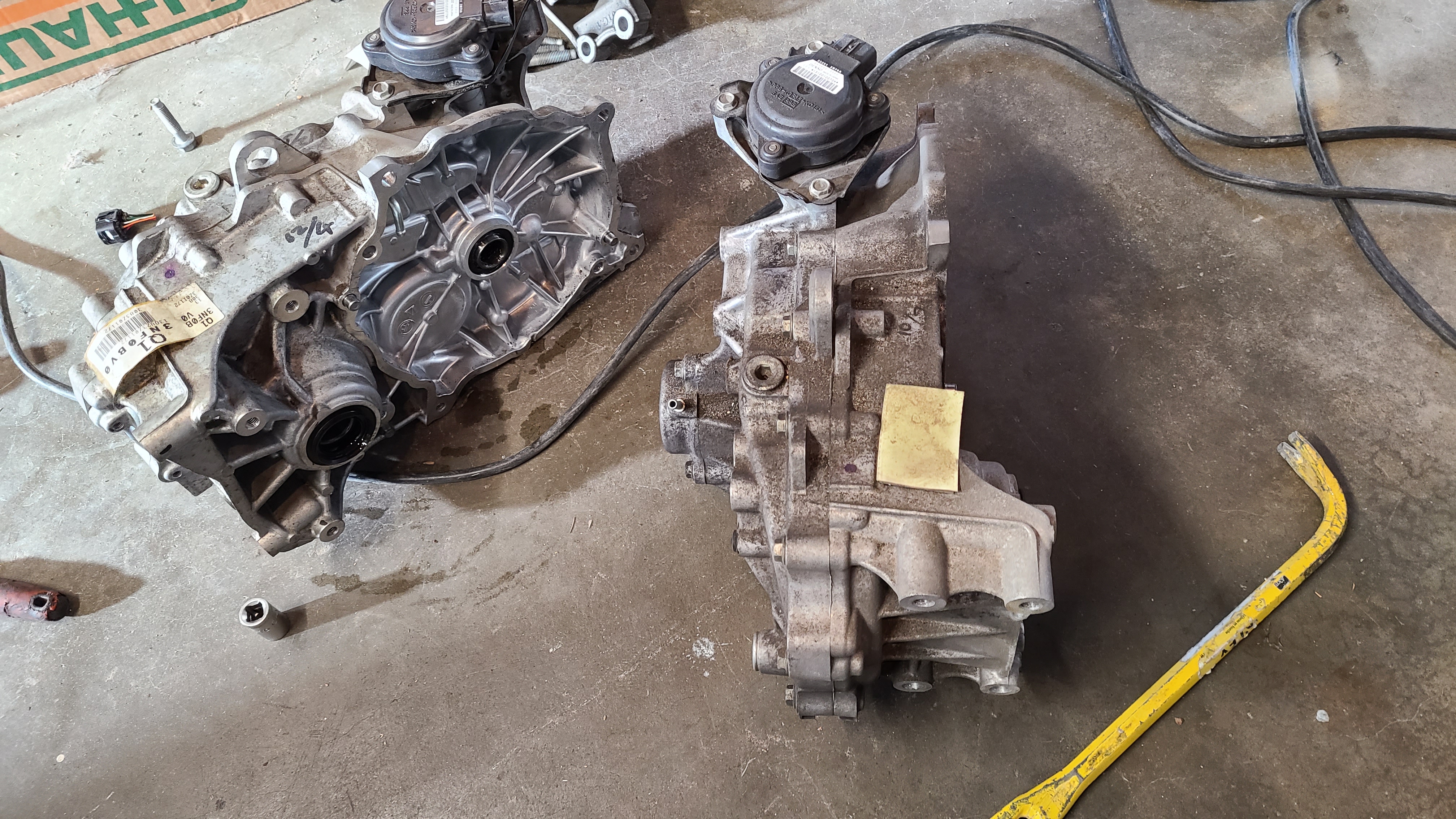

Then drop the transmission out of the car:

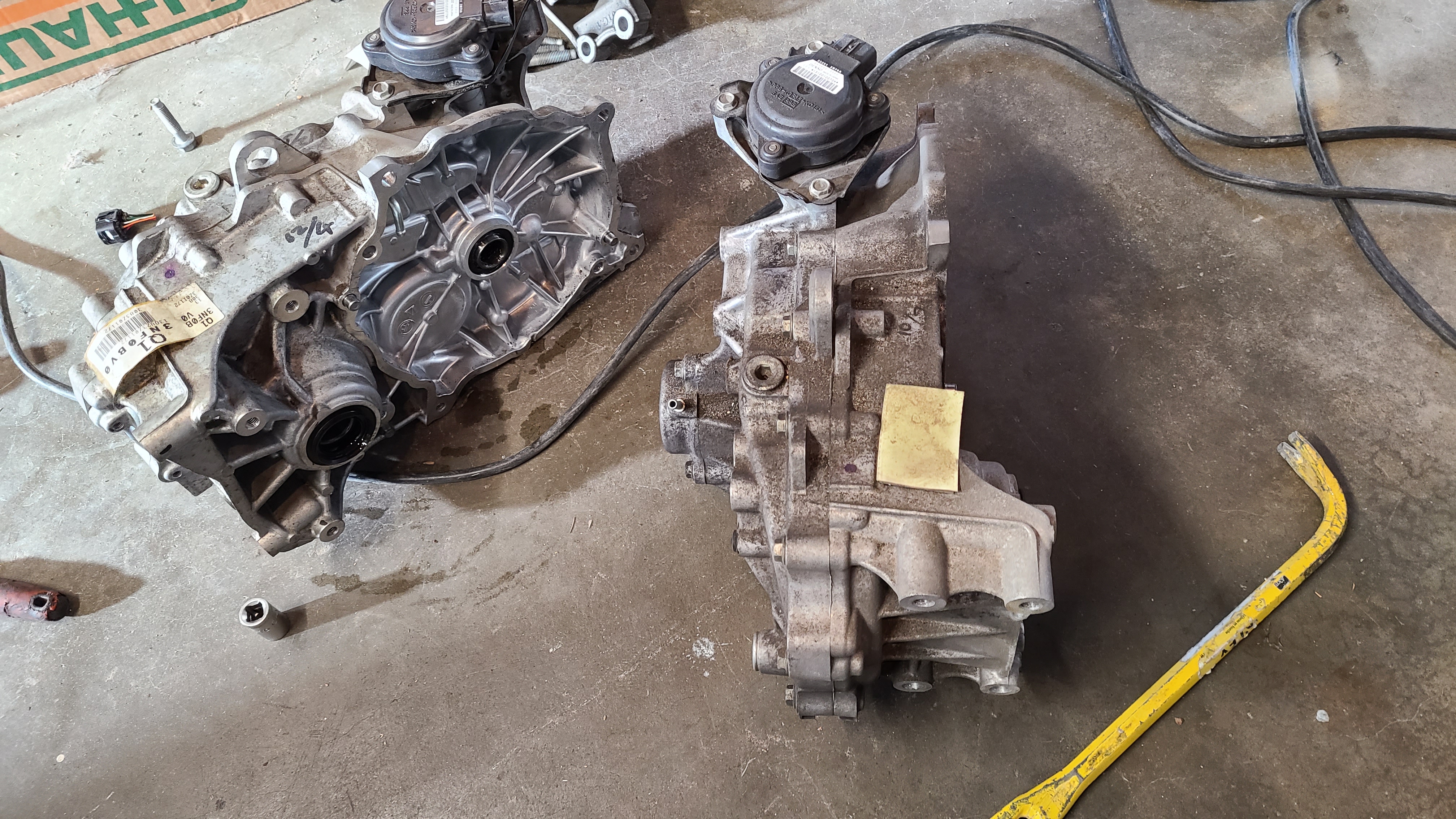

and take the new one and stuff it back in there! Be sure to tighten everything to spec and don't have any bolts left over. If anyone needs a gearbox I have a perfectly good 90k mile one in my garage now, since that wasn't the source of the noise i was chasing

Let me know if there are any questions and I'll expand on any of this.

Cheers,

Marko

About a year ago while messing about with different gear oils, I started hearing a humming noise from my gearbox and was certain that my gearbox was going bad. I then got busy building a sauna and have been ignoring the cars. I kept driving the car with the humming noise and it slowly got a bit louder. It got loud enough that I made time for cars again and long story short, it was my wheel bearing, as the noise was still there after replacing the gearbox. The good news is though, that now I can contribute with a video and how-to on this website for getting this job done

The short and sweet route first, I tried to gopro this process the best that I could and leave out any fluff or bullshit that a ton of youtube videos have these days. Per the timestamps on the gopro this took me 9 hours, but i took several breaks in between as well as lunch and dinner, so expect this to be a most of the day type of a job.

https://www.youtube.com/watch?v=4RfyN_ZOt-g

Special tools required:

- 32mm socket for axle nut

- New o-ring for motor output if yours is old (need to dig up what this part number is still)

- Lithium-based grease including molybdenum disulphide.

Torque Specs:

Front Axle Nut - 135 ft lbs

Tie Rod Nut - 25 ft lbs

Transmission Attachment Bolts (16mm) - 37 ftlbs

Transmission Mount Bolts (18mm) - 74 ft lbs

Smaller 13 mm bolts, 18 ft lbs

Upright Bolts to Strut 103 ft lbs

Lug Nuts 85 ft lbs

The short and sweet of it is, this can all be done with basic tools and a bit of muscle. The gearbox itself weighs about 30 lbs so it is not the easiest thing to bench press up and down, but totally doable.

Going to keep the how-to portion of pictures/text short, as the video should cover things in better detail.

Start by jacking up the car, I chose these subframe points to put the jacks under:

Pull out the 12V battery as well as the high voltage battery jumper in front of the rear seats.

After draining the gearbox oil, then pull out both axles (I learned this about half way through the video, can't get a couple of the transmission bolts off the motor without also pulling the passenger side axle). The mount for the passenger side axle is ultimately what gets in the way. Luckily the axles come out with fairly little effort.

Once the axles are out, support the bottom of the motor with a jack or a wooden support stand. This will allow you to take off the front and rear motor mounts, held on by four 18mm bolts each. The front mount also has a smaller nut holding it onto a rubber mount, once you remove this, the whole front mount comes out of the car.

With all the transmission mounting bolts out of the way and the front mount out of the car, you should be able to put a prybar under the transmission about here and pop the transmission loose:

Then drop the transmission out of the car:

and take the new one and stuff it back in there! Be sure to tighten everything to spec and don't have any bolts left over. If anyone needs a gearbox I have a perfectly good 90k mile one in my garage now, since that wasn't the source of the noise i was chasing

Let me know if there are any questions and I'll expand on any of this.

Cheers,

Marko