knightmb

Well-known member

This is more of documentation of my experience diagnosing an issue with a relatives 2018 Nissan Leaf. Hopefully this can provide useful information for anyone else in the future that runs into this dreaded error and left stranded.

It started with a call from a panicked relative early in the morning. They tried to start their Leaf in the early hours and got the dreaded "Service EV System No Power" screen. I wouldn't have time to take a look at until around noon, but what choice did they have short of towing it to Nissan and paying a diagnostic fee?

Anyway, fast forward to around noon, I arrive and bring all my equipment and tools with me. The first thing I noticed was the cabin light looked very weak, hmm.

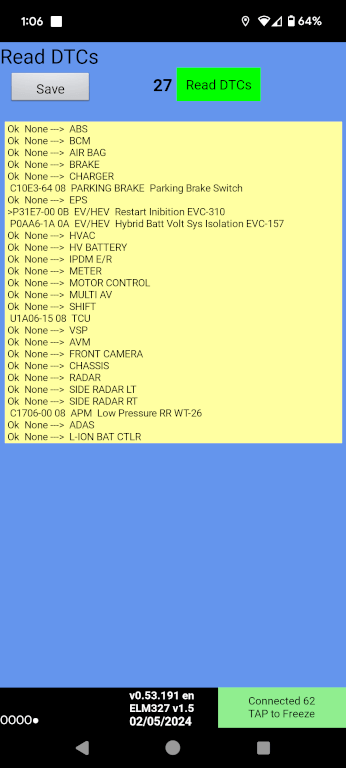

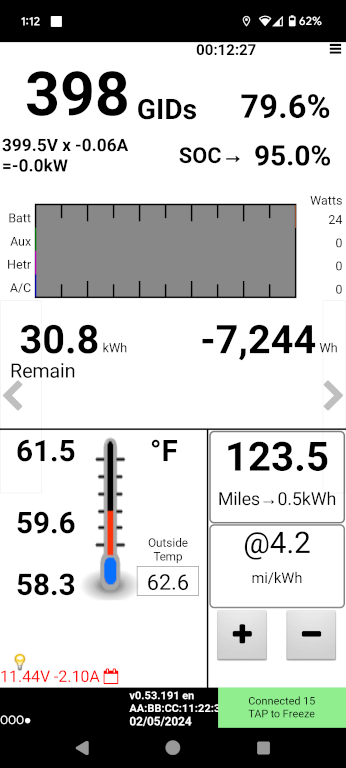

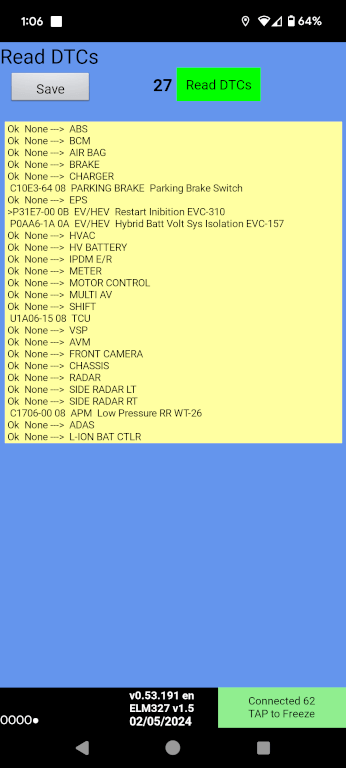

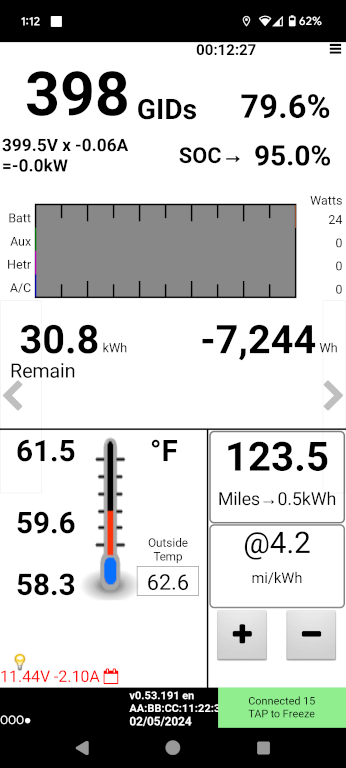

So this is what LeafSpy was able to tell me about their issue (screen shot below). Yeah, that does not look good. But then I noticed the 12V system voltage, it was really low for just getting the dash switched on in standby mode so I could run LeafSpy. 11.44V with only a 24 watt load? I'm starting to suspect the 12V battery. But I don't want to seem like I'm being bias against the poor 12V battery. So I open the hood to take a look at the 12V battery itself. Well, it's an original Nissan factory battery!

Going by the thick later of dust and dirt, no one has probably touched it in years.

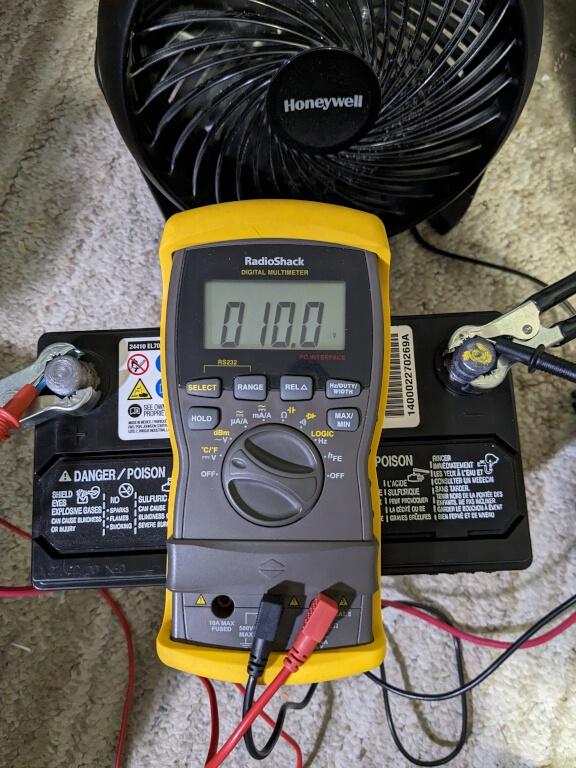

Before I start giving the 12V battery the evil eye, I need to check if that P0AA6-1A code is a real concern. Grabbing my socket set and HV gloves I disconnect the 12V battery from the Leaf. I then find a good grounding spot on the frame and then I remove service disconnect from the center of the pack. I use my multi-meter to check both contacts down in the plug to see if any voltages appear between both sides of the pack and vehicle ground. After a long wait for the capacitance to finally zero out the voltage, I am about to confirm that no voltage leaks were found while testing the battery pack. Something interesting I did see after waiting for 0 volts was that the wind blowing across the Leaf was able to generate some Milli-volts of potential from what I can only guess is static build-up. It was weird to see it detected on the meter, but I am pretty certain that some Milli-volts of static potential would not be enough to set off the safety system for that. Nissan must have coding safe guards from something like that.

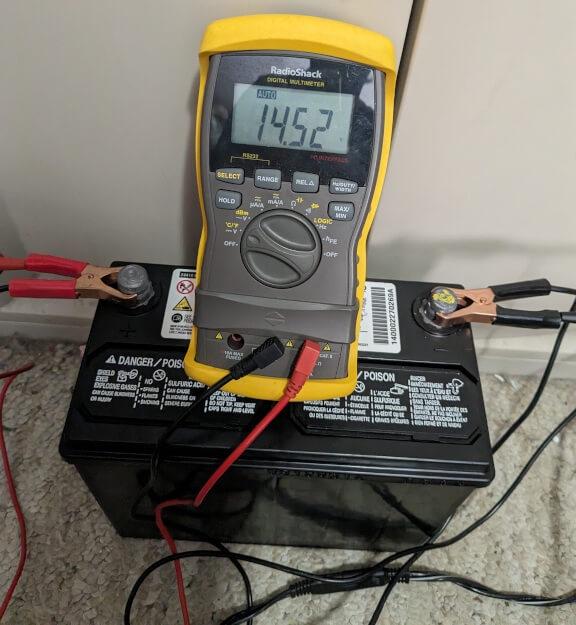

So I carefully put the service disconnect plug back in, bolt everything back together, snap the plastic cover back on the center, etc. My focus will be on the 12V battery now. I measure the voltage of the 12V battery since it's been disconnected from the Leaf for a while now. Low and behold, I seem to get a solid voltage reading of 12.62V. The weather is warmer now than it was in the morning, so maybe the 12V battery just appears to be ok?

Regardless, I'm going to hook a charger to the 12V battery and top it off before connecting it back to the Leaf. Since it appeared to be mostly dead before, I figured it was going to be a long wait to charge it back up before I re-connect it back to the Leaf. Nope, only took an hour to fully charge it.

Well I knew something was wrong then because I was using 1.5A charger and putting 1.5AH back into a battery rated for 43 AH in no way means that it was fully charged at that capacity. It just means the voltage might appear fine, but once a serious load is applied it will probably quickly fail.

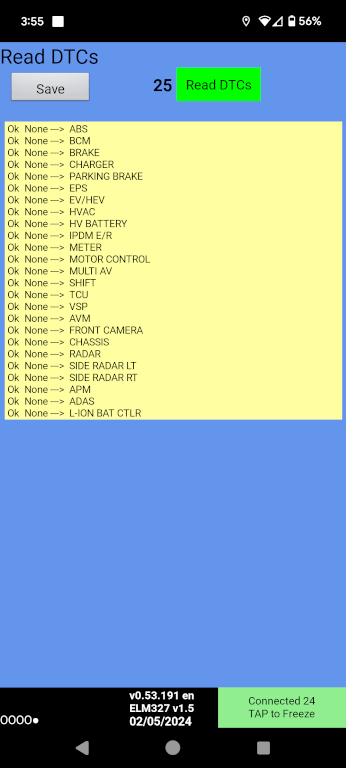

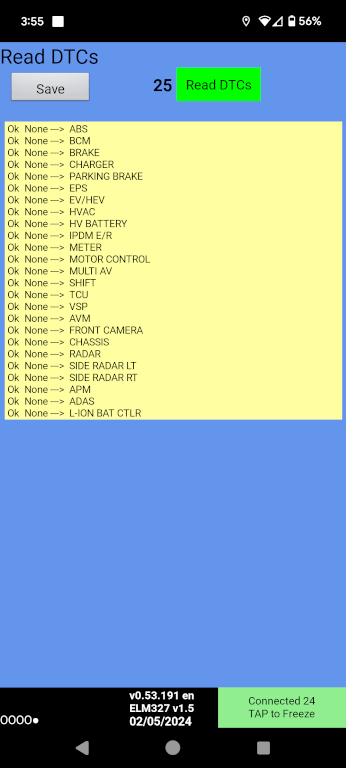

So, I hooked it back into the Leaf anyway to see how it would perform. The voltage appeared to be much more stable now and I was about to clear out all the DTC issues with LeafSpy. I then shut it off, took a 15 minute break, came back to fire it up to see if any more DTC issues arise. Everything appeared to be fine now, not a single DTC, nice!

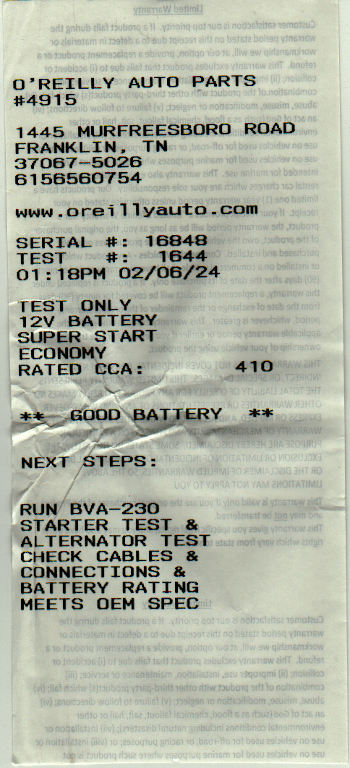

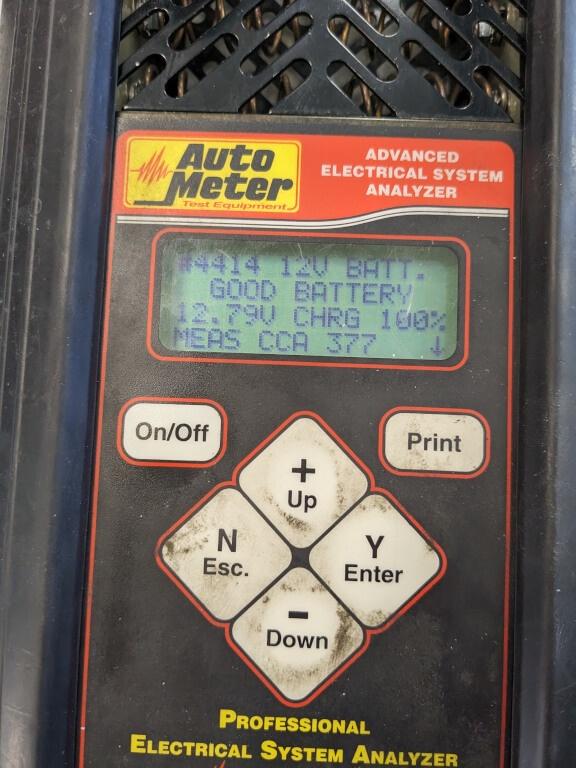

Final conclusion, I blame the 12V battery. Not that it's impossible that if the internal battery was touching the case somewhere, maybe the warmer temperature fixed that? I highly doubt that, so I think this dying 12V battery is making weird things happen. So, I talk with my relative about options, mainly about replacing this +5 year old Nissan OEM battery with something better. I could be wrong of course, but my next step is to do some load test on the 12V battery from various auto-shops to see what they think and finally I will do a full charge/discharge capacity test to see how much capacity the battery actually has. My guess would be it's so low as to be useless when actually called on to produce a lot of power for any extended amount of time. For now, they want to go the route of "please fix forever", so I'm going to have to do some research to see if I can find any 51R LiFePO4 size batteries (so I can drop-in replace it without having to do custom wiring), but not in the full AH size they don't really need 100AH of capacity for the Leaf but more like maybe 25AH to 30AH to avoid spending a fortune on it. For now, I told them I would not trust it drive around very far away if the 12V fails again and just leave the Leaf "on" and turn off all accessories if parked; if they need to run any errands until they get home and then shut it off at home just in case. I also left them my trickle charger and showed them how to keep the 12V battery topped off until a new replacement can be swapped.

At least I saved them a tow truck fee and Nissan diagnostic fee which could have probably resulted in the dealership charging them a fortune to replace the OEM 12V battery with another Nissan generic.

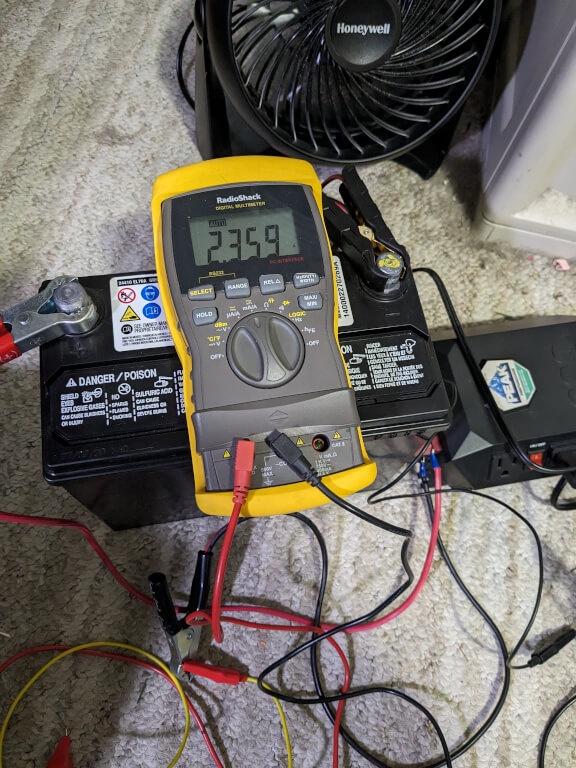

My next topic update will be when I can get a hold of that 12V battery, inspect it for damage or other issues and run it through more detailed testing of it's capacity.

It started with a call from a panicked relative early in the morning. They tried to start their Leaf in the early hours and got the dreaded "Service EV System No Power" screen. I wouldn't have time to take a look at until around noon, but what choice did they have short of towing it to Nissan and paying a diagnostic fee?

Anyway, fast forward to around noon, I arrive and bring all my equipment and tools with me. The first thing I noticed was the cabin light looked very weak, hmm.

So this is what LeafSpy was able to tell me about their issue (screen shot below). Yeah, that does not look good. But then I noticed the 12V system voltage, it was really low for just getting the dash switched on in standby mode so I could run LeafSpy. 11.44V with only a 24 watt load? I'm starting to suspect the 12V battery. But I don't want to seem like I'm being bias against the poor 12V battery. So I open the hood to take a look at the 12V battery itself. Well, it's an original Nissan factory battery!

Going by the thick later of dust and dirt, no one has probably touched it in years.

Before I start giving the 12V battery the evil eye, I need to check if that P0AA6-1A code is a real concern. Grabbing my socket set and HV gloves I disconnect the 12V battery from the Leaf. I then find a good grounding spot on the frame and then I remove service disconnect from the center of the pack. I use my multi-meter to check both contacts down in the plug to see if any voltages appear between both sides of the pack and vehicle ground. After a long wait for the capacitance to finally zero out the voltage, I am about to confirm that no voltage leaks were found while testing the battery pack. Something interesting I did see after waiting for 0 volts was that the wind blowing across the Leaf was able to generate some Milli-volts of potential from what I can only guess is static build-up. It was weird to see it detected on the meter, but I am pretty certain that some Milli-volts of static potential would not be enough to set off the safety system for that. Nissan must have coding safe guards from something like that.

So I carefully put the service disconnect plug back in, bolt everything back together, snap the plastic cover back on the center, etc. My focus will be on the 12V battery now. I measure the voltage of the 12V battery since it's been disconnected from the Leaf for a while now. Low and behold, I seem to get a solid voltage reading of 12.62V. The weather is warmer now than it was in the morning, so maybe the 12V battery just appears to be ok?

Regardless, I'm going to hook a charger to the 12V battery and top it off before connecting it back to the Leaf. Since it appeared to be mostly dead before, I figured it was going to be a long wait to charge it back up before I re-connect it back to the Leaf. Nope, only took an hour to fully charge it.

Well I knew something was wrong then because I was using 1.5A charger and putting 1.5AH back into a battery rated for 43 AH in no way means that it was fully charged at that capacity. It just means the voltage might appear fine, but once a serious load is applied it will probably quickly fail.

So, I hooked it back into the Leaf anyway to see how it would perform. The voltage appeared to be much more stable now and I was about to clear out all the DTC issues with LeafSpy. I then shut it off, took a 15 minute break, came back to fire it up to see if any more DTC issues arise. Everything appeared to be fine now, not a single DTC, nice!

Final conclusion, I blame the 12V battery. Not that it's impossible that if the internal battery was touching the case somewhere, maybe the warmer temperature fixed that? I highly doubt that, so I think this dying 12V battery is making weird things happen. So, I talk with my relative about options, mainly about replacing this +5 year old Nissan OEM battery with something better. I could be wrong of course, but my next step is to do some load test on the 12V battery from various auto-shops to see what they think and finally I will do a full charge/discharge capacity test to see how much capacity the battery actually has. My guess would be it's so low as to be useless when actually called on to produce a lot of power for any extended amount of time. For now, they want to go the route of "please fix forever", so I'm going to have to do some research to see if I can find any 51R LiFePO4 size batteries (so I can drop-in replace it without having to do custom wiring), but not in the full AH size they don't really need 100AH of capacity for the Leaf but more like maybe 25AH to 30AH to avoid spending a fortune on it. For now, I told them I would not trust it drive around very far away if the 12V fails again and just leave the Leaf "on" and turn off all accessories if parked; if they need to run any errands until they get home and then shut it off at home just in case. I also left them my trickle charger and showed them how to keep the 12V battery topped off until a new replacement can be swapped.

At least I saved them a tow truck fee and Nissan diagnostic fee which could have probably resulted in the dealership charging them a fortune to replace the OEM 12V battery with another Nissan generic.

My next topic update will be when I can get a hold of that 12V battery, inspect it for damage or other issues and run it through more detailed testing of it's capacity.