keepitrunning

Member

- Joined

- Mar 7, 2022

- Messages

- 10

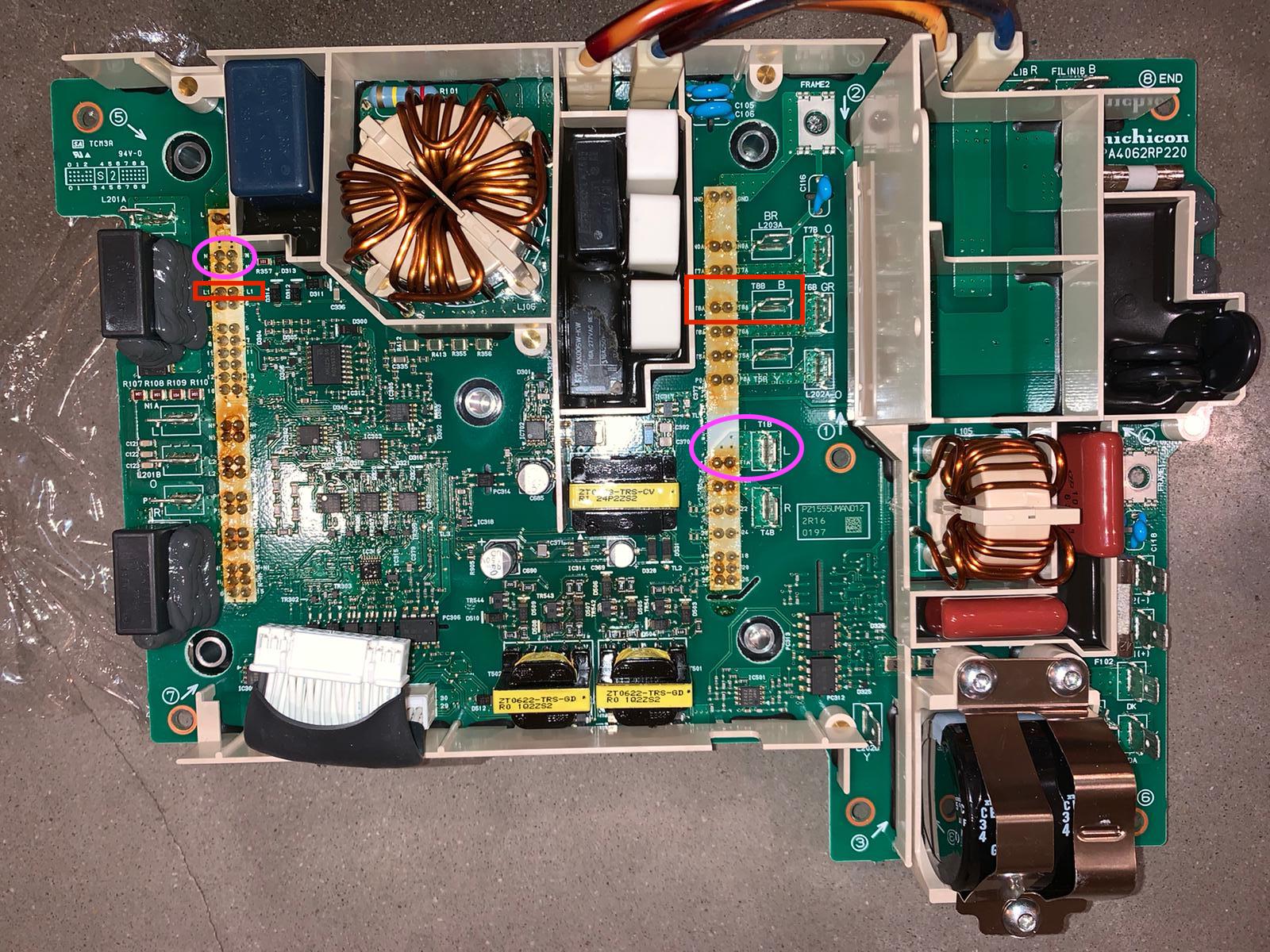

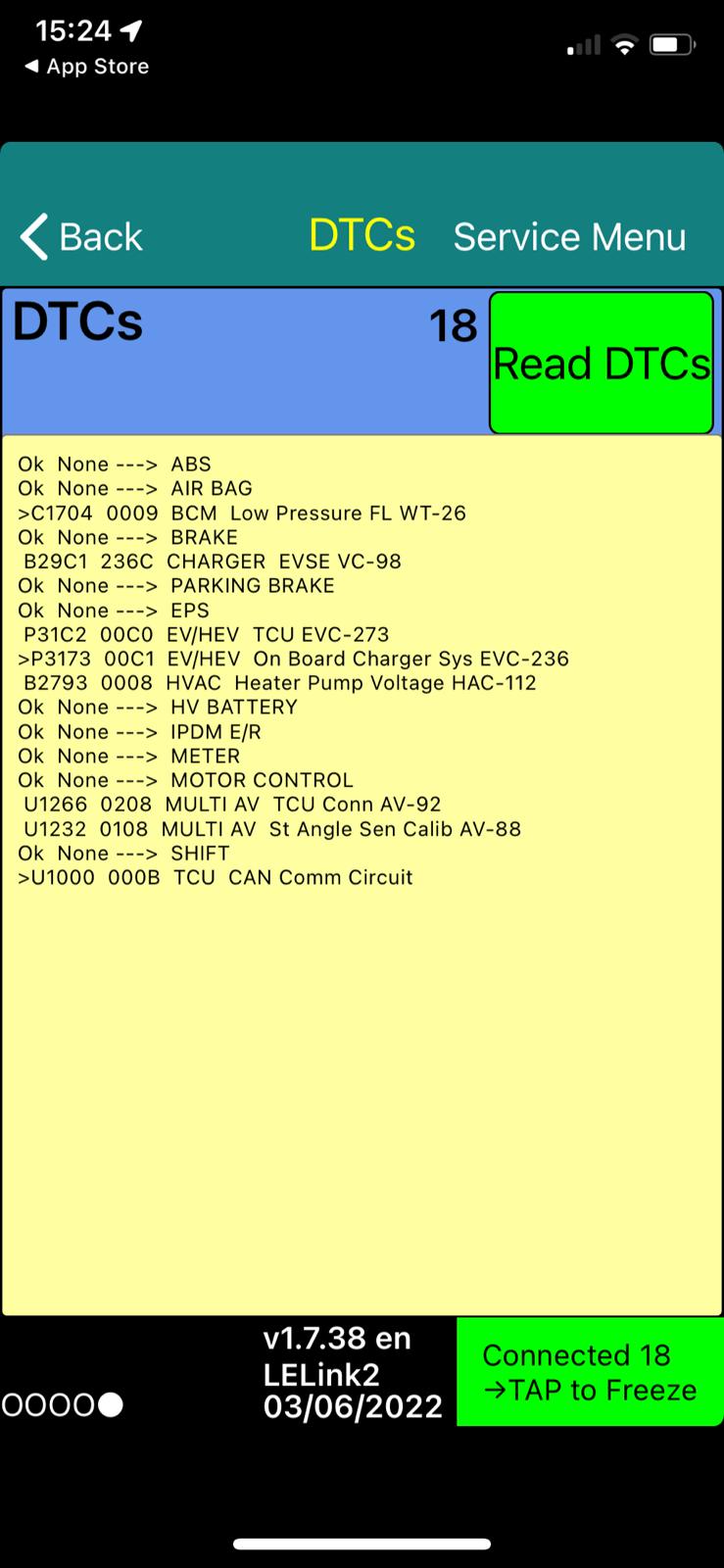

2012 model, 3.3kw charger

3NA6A sticker on charger appears to have software update to 3NA7A as recognized in LeafSpy Pro

Just in case I missed an important step, I didn't try clearing DTCs and retry charging before taking everything apart and removing the OBC boards. The local dealer may or may not have attempted this when they gave a quick and dirty diagnosis for "needs OBC replacement".

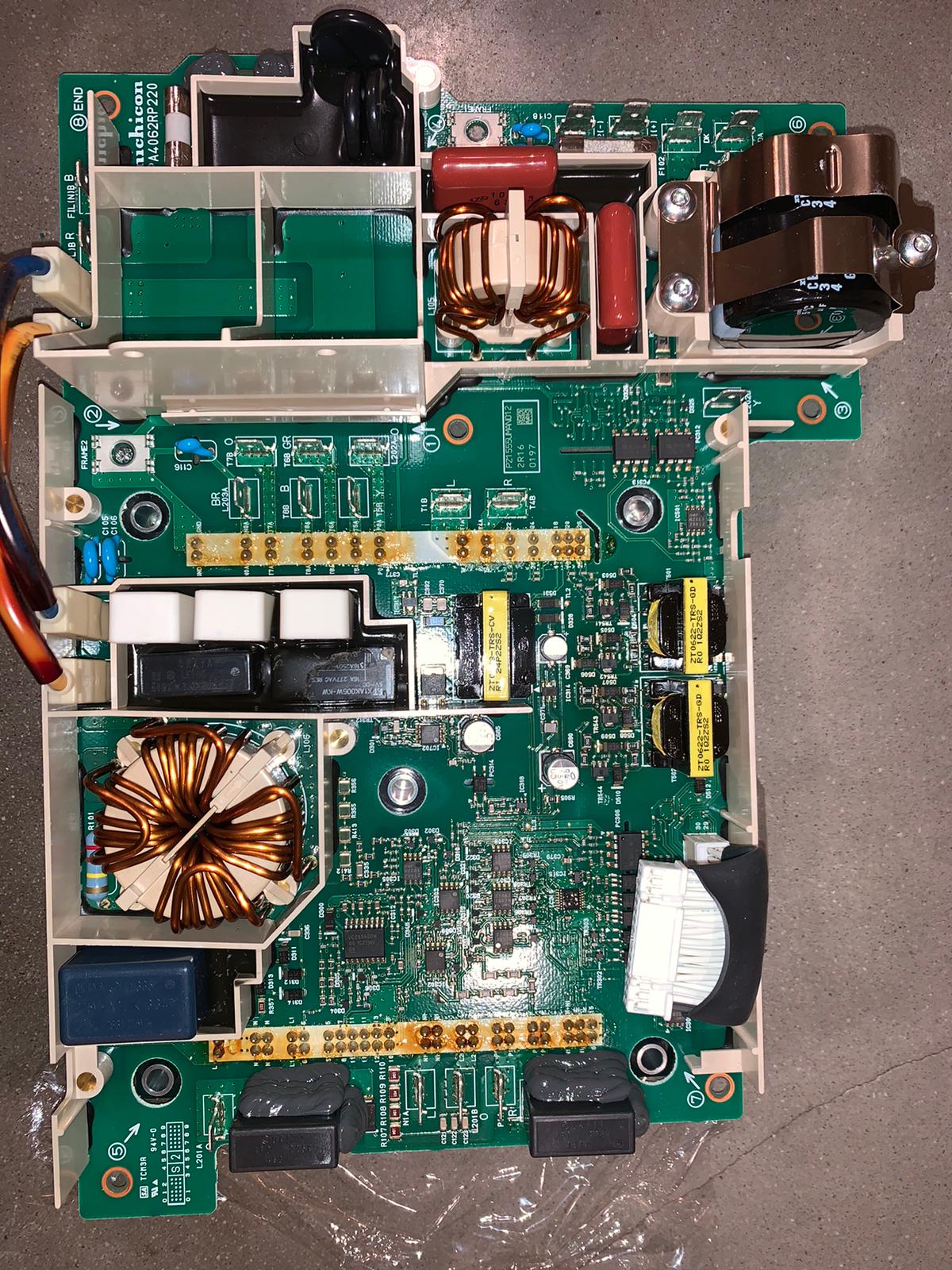

*That being said, I cannot find any point of failure on the boards.*

I have been using a Duosida cord style evse at home and have charged exclusively at home on same cord for 3 years we've owned it. Just noticed it wasn't charged one morning and can't point to any obvious power/weather event. After OBC charger failed, I tested on L2 at dealer (not working), DC chademo - working. Failed test/Not a candidate for the diode quick and dirty solution. Symptoms are first light blinks, typical starting clunks and then quits after about 5 seconds - this set of symptoms frequently points to a failed section of the lower board for which I can't find any failures.

For 3 days, I've combed the delightfully detailed posts from so many helpful experts here, especially @nlspace, but my exact symptoms only match a few others who managed to obtain alternate units and didn't follow up repair of their bad chargers. It would be great to fix this one because the dealer replacement option is on backorder with no ETA.

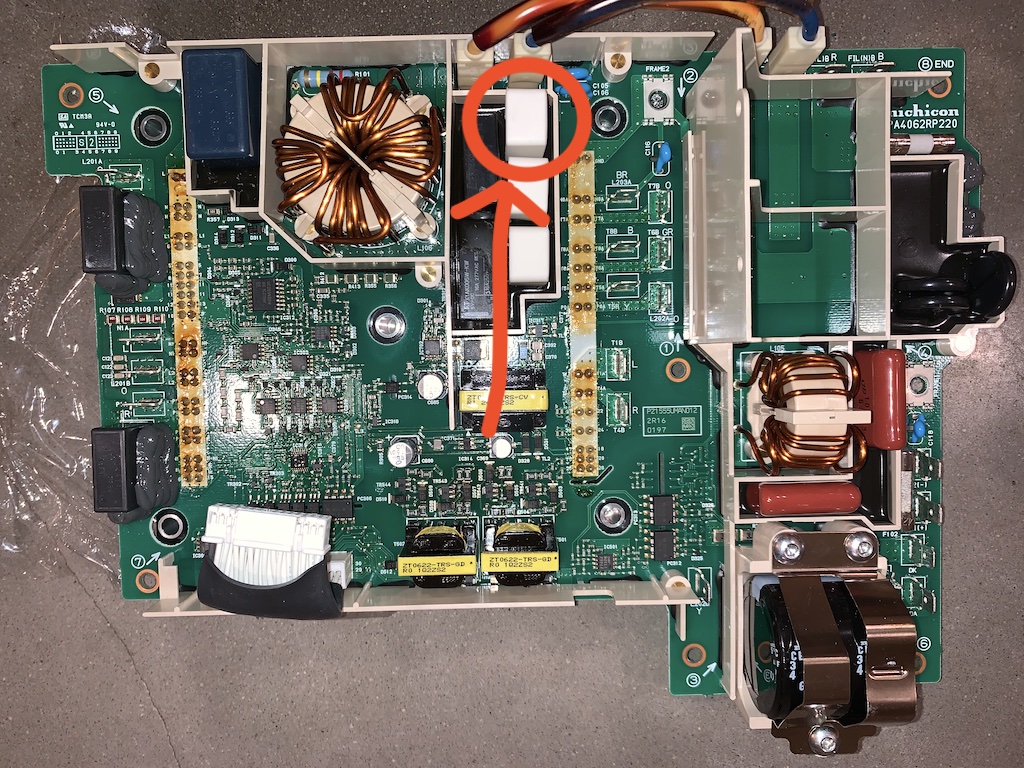

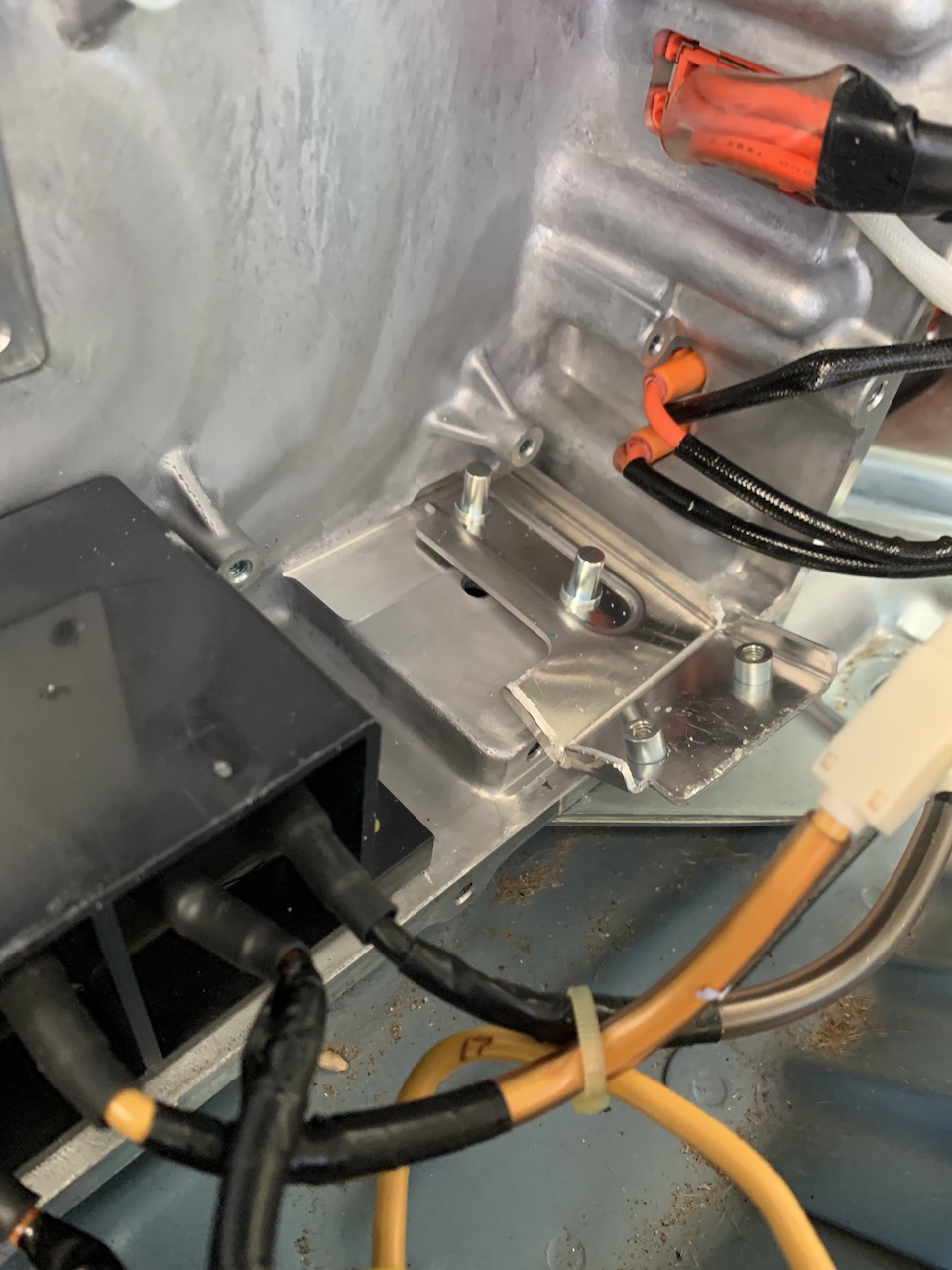

My charger boards appear to have no physically damaged components. I've used the test equipment I have to provide all the other notes below which so far seem clean - but I hope an expert can detect an error I might have made. There does not appear to be any physical damage to the waffle plate. There was no smoke residue anywhere inside the charger or on any board, etc. There are no unusual odors etc. No hot spots on the boards neither.

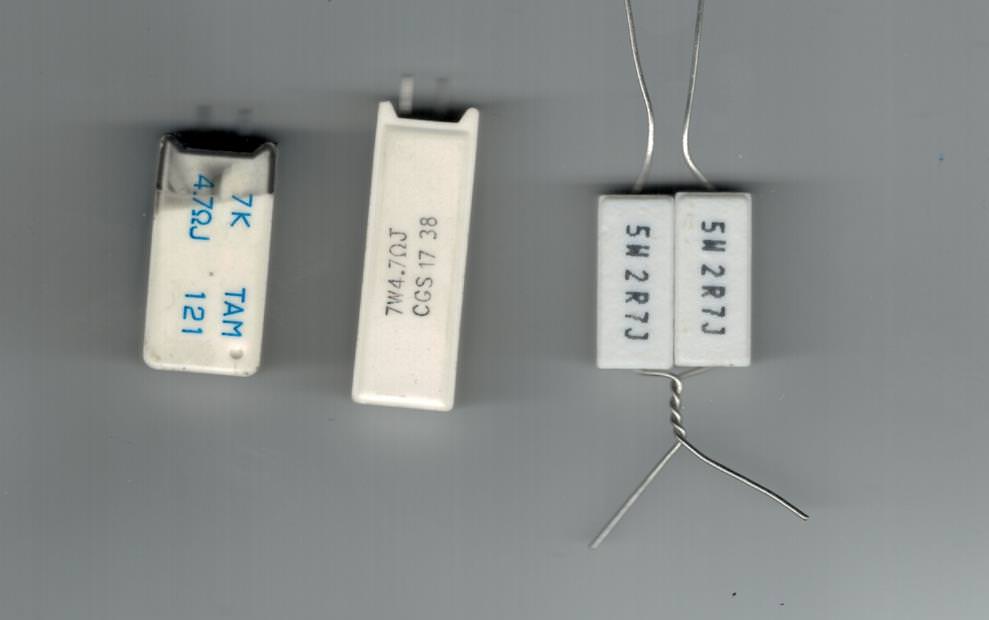

I can visually verify the power resistors, relay and LE105 capacitor as intact, but I don't have a test procedure for them. Somewhere I think I read a method to check the fused resistor in the white power resistor with green text from external pins but I cannot find it now. For now I will list these as known unknowns.

***Known Unknowns*** :

3 white power resistors (appear fine),

LE105 capacitor has a very very very slight bulge. A local electronics guy thought it looked fine - unable to test as yet.

waffle board (looks fine, need test procedure referenced in some posts)

Here I have excerpted @nlspace testing advice I gathered from multiple posts to present the test procedure and my results together. (Thank you @nlspace for your many contributions and explanations.)

Tested Components:

Diode above 4 resistor series (R107 R108...) -

:: retty sure this one is okay :

retty sure this one is okay :

In diode test mode, open in 1direction of polarity, .63Mohm in the other.

In resistance mode, appears to be charging capacitor and resistance is increasing and .63Mohm fixed in other polarity.

A) Does your big L201 inductor have continuity or might it be blown also? Measure for continuity between the two orange wires leading to the inductor. It should read a very low, close to zero Ohms if okay.

:::Measured 0.35 ohms

B) Is the big 2700uF capacitor okay or might it be shorted? Measure the capacitor between the red and black wires. If it reads close to zero ohms then it is shorted

:::Measured 5K ohms and climbs rapidly

C) There are 3 fuses on that board that need to be checked for continuity also. F101, 102, 103.

:::

F101 (Ceramic) good

F102 (glass with sand) good

F103 (glass held by RTV) good

D) Measure for resistance between the solder junctions labelled "8" and "7" on the seventh row down on the left hand side.

:::0.2 ohms ? What does this mean

E) check for continuity on the those black nickel-sized lollypops next to the fuses in the black potted area.

:::No continuity on any of 3 lollypops - what should be expected here?

F) Also check continuity across that little glass tube (lightning arrestor) next to that.

:::No continuity

G) Do you still have the OEM level 1 version EVSE?

:::no, never had

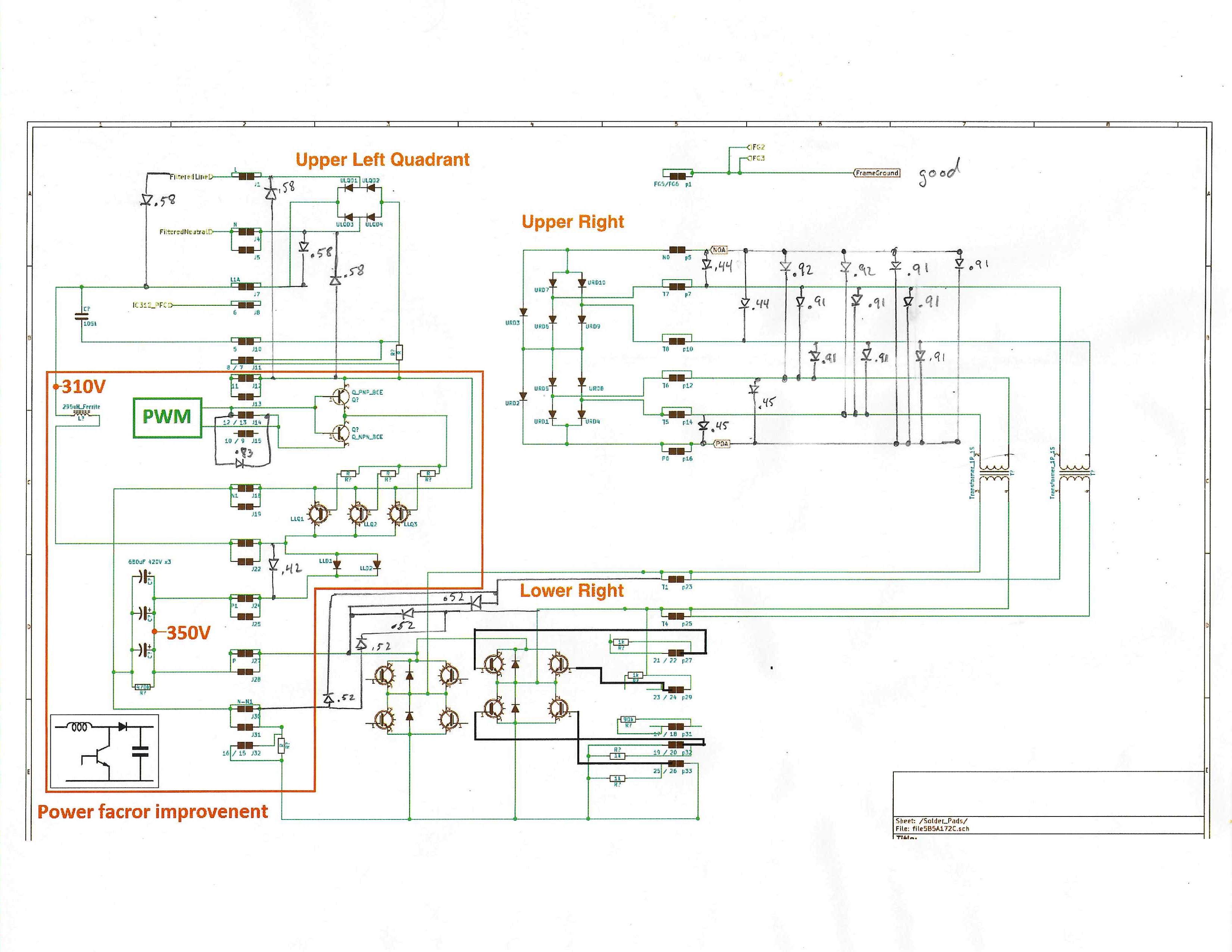

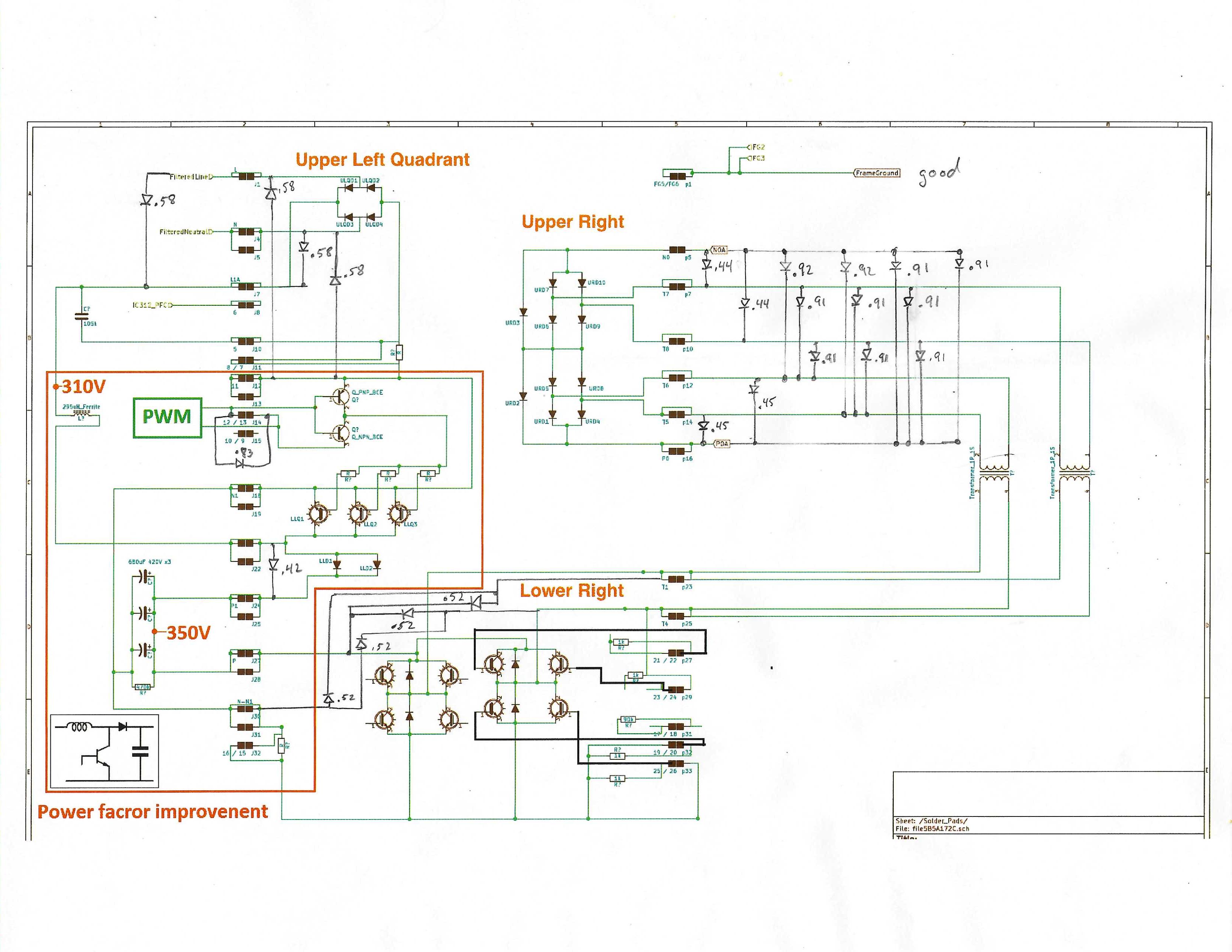

H) When you pull the board there are some diode voltage checks that you can do to make sure the waffle plate is not damaged.

:: oes someone know the link to the frequently referenced tests?

oes someone know the link to the frequently referenced tests?

I) On the top board, D547 is a double diode pair.

:::Tests OK.

J)And just to double check, are the N1 and P1 pins on the left side shorted to the T1 and T4 pins on the right hand side of the waffle plate?

:::In diode test mode, N1 is shorted to T1A and T4A in one direction (N1 shorts to P1 in this same polarity), and P1 is shorted to T1A and T4A in the opposite direction.

K) You should probably check the diode drops of the waffle plate to make sure that it is not shorted/damaged, especially the AC rectifier section and the PFC.

:::I think this is a reference to same as H) above.

L) large 300µF cap in lower right

:::resistance climbing, no shorted

Can anyone point to what I might be missing?

3NA6A sticker on charger appears to have software update to 3NA7A as recognized in LeafSpy Pro

Just in case I missed an important step, I didn't try clearing DTCs and retry charging before taking everything apart and removing the OBC boards. The local dealer may or may not have attempted this when they gave a quick and dirty diagnosis for "needs OBC replacement".

*That being said, I cannot find any point of failure on the boards.*

I have been using a Duosida cord style evse at home and have charged exclusively at home on same cord for 3 years we've owned it. Just noticed it wasn't charged one morning and can't point to any obvious power/weather event. After OBC charger failed, I tested on L2 at dealer (not working), DC chademo - working. Failed test/Not a candidate for the diode quick and dirty solution. Symptoms are first light blinks, typical starting clunks and then quits after about 5 seconds - this set of symptoms frequently points to a failed section of the lower board for which I can't find any failures.

For 3 days, I've combed the delightfully detailed posts from so many helpful experts here, especially @nlspace, but my exact symptoms only match a few others who managed to obtain alternate units and didn't follow up repair of their bad chargers. It would be great to fix this one because the dealer replacement option is on backorder with no ETA.

My charger boards appear to have no physically damaged components. I've used the test equipment I have to provide all the other notes below which so far seem clean - but I hope an expert can detect an error I might have made. There does not appear to be any physical damage to the waffle plate. There was no smoke residue anywhere inside the charger or on any board, etc. There are no unusual odors etc. No hot spots on the boards neither.

I can visually verify the power resistors, relay and LE105 capacitor as intact, but I don't have a test procedure for them. Somewhere I think I read a method to check the fused resistor in the white power resistor with green text from external pins but I cannot find it now. For now I will list these as known unknowns.

***Known Unknowns*** :

3 white power resistors (appear fine),

LE105 capacitor has a very very very slight bulge. A local electronics guy thought it looked fine - unable to test as yet.

waffle board (looks fine, need test procedure referenced in some posts)

Here I have excerpted @nlspace testing advice I gathered from multiple posts to present the test procedure and my results together. (Thank you @nlspace for your many contributions and explanations.)

Tested Components:

Diode above 4 resistor series (R107 R108...) -

::

In diode test mode, open in 1direction of polarity, .63Mohm in the other.

In resistance mode, appears to be charging capacitor and resistance is increasing and .63Mohm fixed in other polarity.

A) Does your big L201 inductor have continuity or might it be blown also? Measure for continuity between the two orange wires leading to the inductor. It should read a very low, close to zero Ohms if okay.

:::Measured 0.35 ohms

B) Is the big 2700uF capacitor okay or might it be shorted? Measure the capacitor between the red and black wires. If it reads close to zero ohms then it is shorted

:::Measured 5K ohms and climbs rapidly

C) There are 3 fuses on that board that need to be checked for continuity also. F101, 102, 103.

:::

F101 (Ceramic) good

F102 (glass with sand) good

F103 (glass held by RTV) good

D) Measure for resistance between the solder junctions labelled "8" and "7" on the seventh row down on the left hand side.

:::0.2 ohms ? What does this mean

E) check for continuity on the those black nickel-sized lollypops next to the fuses in the black potted area.

:::No continuity on any of 3 lollypops - what should be expected here?

F) Also check continuity across that little glass tube (lightning arrestor) next to that.

:::No continuity

G) Do you still have the OEM level 1 version EVSE?

:::no, never had

H) When you pull the board there are some diode voltage checks that you can do to make sure the waffle plate is not damaged.

::

I) On the top board, D547 is a double diode pair.

:::Tests OK.

J)And just to double check, are the N1 and P1 pins on the left side shorted to the T1 and T4 pins on the right hand side of the waffle plate?

:::In diode test mode, N1 is shorted to T1A and T4A in one direction (N1 shorts to P1 in this same polarity), and P1 is shorted to T1A and T4A in the opposite direction.

K) You should probably check the diode drops of the waffle plate to make sure that it is not shorted/damaged, especially the AC rectifier section and the PFC.

:::I think this is a reference to same as H) above.

L) large 300µF cap in lower right

:::resistance climbing, no shorted

Can anyone point to what I might be missing?