bowthom

Well-known member

I would be interested in heat rise tests of the battery when "accelerated" charging. How much does it increase compared to normal 3.3kWh charging.

I'm interested in doing this mod.

I'm interested in doing this mod.

Phil has already looked into it and published his observation. He implemented a similar mod a year ago.bowthom said:I would be interested in heat rise tests of the battery when "accelerated" charging. How much does it increase compared to normal 3.3kWh charging.

Ingineer said:The temp does rise 1-2 degrees higher, but then it drops faster, so overall I think the pack's average temp/time is less than when exposed to 3.3kW.

It's 66Ah rated capacity for the pack and 33Ah for individual cells. Strictly speaking, the LEAF does not use LiPo batteries, but similar principles apply.JasonA said:These are (62ah?) cells so we're not even in the region of 1/4c charge rate.

The Leaf uses 96 Prismatic cells/packs.. I mean its early and I'm just hitting the coffee..surfingslovak said:66Ah rated capacity. Strictly speaking, the LEAF does not use LiPo batteries, but similar principles apply.JasonA said:These are (62ah?) cells so we're not even in the region of 1/4c charge rate.

Oh good. I was up at 5:15 for the i3 unveiling. Lots of coffee needed. Yes, 48 modules with 66 Ah each, 96 cell-pairs, and 192 cells with 33 Ah each. The cells are lithium manganese oxide. The LiPo designation stems from the composition of the electrolyte. The LMO cells from AESC in the LEAF use LiPF6 (Lithium hexafluorophosphate), which is different from a LiPo battery. True LiPos don't have a liquid electrolyte but instead use a dry electrolyte polymer separator sheet that resembles a thin plastic film. While LMO cells theoretically reach maximum charge at 4.17V, they will readily go to a higher voltage. Even 4.3V and higher is possible. You might want to read this presentation I put together in 2011. I would recommend using the LMO acronym when referring to LEAF cells. Not to derail this thread, but would you know what the cathode material was in the LiPos you use?JasonA said:EDIT: Now the coffee is kicking in----- They are LiOn cells.. same voltage. I'd like to know because I bought a few Leaf cells and they sure charge right up to 4.20 volts.[/url]

There are some older threads, but it won't hurt to start something more specific on cell alternatives and replacement. If LiCo stands for lithium cobalt oxide, then that would be another difference. The LEAF uses manganese instead of cobalt, which increases safety and reduces cost. Cobalt cells reach their theoretical max energy at a higher voltage than manganese cells. They have higher energy density and lower thermal runaway, which might explain some of the RC incidents you described in your earlier posts.JasonA said:We can always start a thread (I'm currently working on a larger pack for the Leaf) in the Batteries & Charging forum.. but to answer your question, most of the LiPo's I use are of the LiCo substrate formula.

surfingslovak said:Phil has already looked into it and published his observation. He implemented a similar mod a year ago.bowthom said:I would be interested in heat rise tests of the battery when "accelerated" charging. How much does it increase compared to normal 3.3kWh charging.

Ingineer said:The temp does rise 1-2 degrees higher, but then it drops faster, so overall I think the pack's average temp/time is less than when exposed to 3.3kW.

Where can I buy one of these modules? I saw Jeremy with one as well and I've never been able to find a discussion about them on this forum.JasonA said:I'd like to know because I bought a few Leaf cells and they sure charge right up to 4.20 volts.

I know Jeremy bought his from Autobeyours. I got mine from a yard in Sun Valley (junk yard capital of California).gbarry42 said:Where can I buy one of these modules? I saw Jeremy with one as well and I've never been able to find a discussion about them on this forum.JasonA said:I'd like to know because I bought a few Leaf cells and they sure charge right up to 4.20 volts.

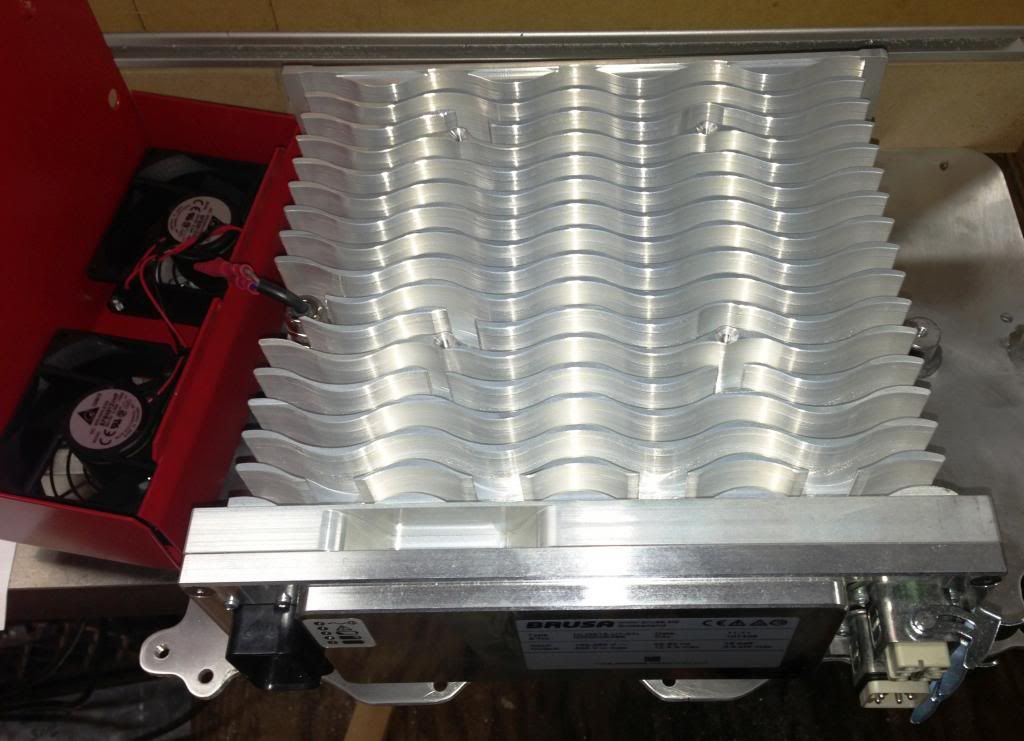

JasonA said:I'm actually looking at a few slightly wrecked Leaf's right now (with DCQC) or.. I'm thinking about a RAV4ev and going all out on the Brusa's..

nope, 11's and 12's..mwalsh said:JasonA said:I'm actually looking at a few slightly wrecked Leaf's right now (with DCQC) or.. I'm thinking about a RAV4ev and going all out on the Brusa's..

You run across any junked '13s yet? Could do with spending less than $90 for that passenger side sunvisor.

This looks fantastic! Well done.KillaWhat said:b]OOOOoooo Pretty!!![/b]

The "clear warnings" toggle is the one you want. It's listed as "clear error latch" bit 6 of the 618 message. Send a 1 with 0 volts and 0 amps. Comments for that message are "Error should only be cleared, when command values are zero"

Enter your email address to join: