edatoakrun said:

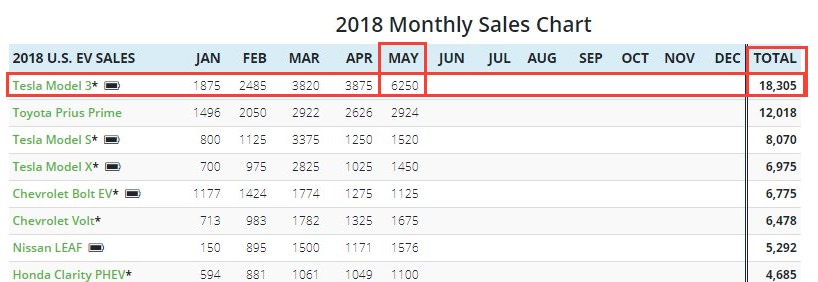

Estimated 6,250 M3 sales in USA in May:

https://insideevs.com/tesla-model-3-sales-may-2018-u-s/

Quite a bit short of most recent 5k/week- 6k/week production by June-July claims from TSLA.

Anyone heard when/if model 3 production restarted after the last production shutdown?

I didn't see that coming: Ed not understanding the difference between

production and

sales, particularly in light of what appears to be an attempt to divert sales to Canada and delay deliveries into 3Q to avoid the 200K tax credit milestone.

As I've said before, June's numbers will probably look even worse, as will Tesla's official 2Q numbers when released in early July and I'm sure the likes of Ed will chime in to tell us all about the "huge miss".

My own estimate for May was 5,982, so I probably slightly overestimated the number of Canadian deliveries.

For June, my estimates are as follows. My estimates are "conservative" in that I am estimating high on the production side for the purposes of determining whether 200K will be crossed in June or July, so assuming "best case" production numbers to see what it would take to defer until 3Q. I am estimating 6K/week during the last week of June, but realistically they will probably only be at 5K.

Production (not sales Ed, there is a difference): 21,000

Delivery pipeline lagged potential sales: 16,500

Diversions to Canada: 4,300

Shipments to US delivery centers but not sold until July 1: 9,000

Net actual June sales: 3,200

End of June "cars in transit" ready to be sold on July 1: 12,000 (higher than the 9,000 which represents the cars built in June, but an additional 3,000 cars built in May are in this group)

If we assume a 5K/week build rate for the last week of June and throughout July, the total number of cars sold in July should be in the neighborhood of 30-31,000 (counting the 12,000 "in transit")

Sure, this number is not sustainable due to the temporary stockpile, but August & September should be able to sustain a 20K/month rate. That's a nice 70K quarter! For comparison,

TOTAL 4Q17 US EV sales (BEV + PHEV combined) was 57,600.

but I'm not optimistic that the firmware community at large is up for the task of writing code up to the standards of DO-178B or equivalent. The airline industry has proven that commercial software can be extremely reliable but their product cycles and marketing requirements are obviously different.

but I'm not optimistic that the firmware community at large is up for the task of writing code up to the standards of DO-178B or equivalent. The airline industry has proven that commercial software can be extremely reliable but their product cycles and marketing requirements are obviously different.